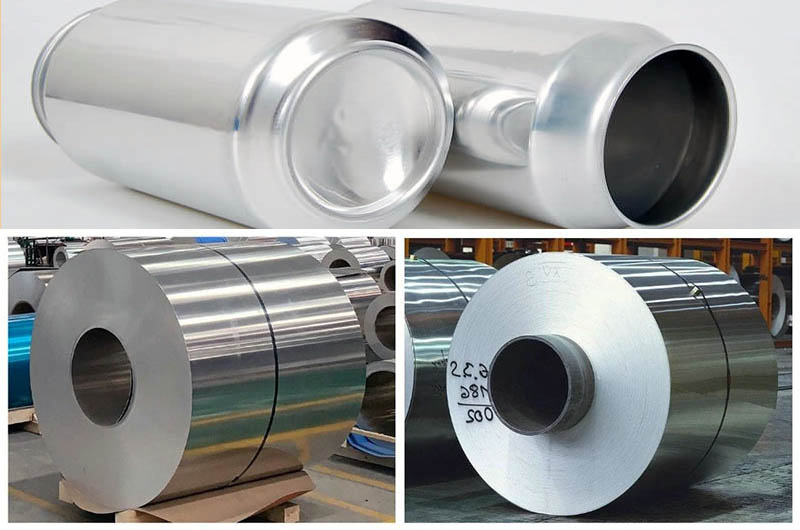

3004 and 3104 H19 aluminum coil and strip are ideal for beverage can production due to their excellent deep drawing capabilities and ductility. They can perfectly adapt to the high-speed stamping process, ensure production efficiency and product quality stability, and provide reliable guarantee for the production of beverage cans.

3004 3104 H19 Aluminum Coil Strip for Can Body deep drawing performance

Deep drawing ability refers to the degree of deformation that a material can withstand when subjected to punching forces. 3004 and 3104 aluminum coil strips have high strength in the H19 state, allowing them to maintain a stable shape during the stamping process and are not prone to cracking or deformation. This high-strength feature enables them to withstand high-frequency stamping on high-speed stamping machines, ensuring production efficiency and product quality stability.

3004 3104 H19 Aluminum Coil Strip for Can Body ductility

Ductility refers to the ability of a material to plastically deform when subjected to external forces. 3004 and 3104 aluminum coil strips have excellent ductility in the H19 state, can be easily stretched and formed, and are not prone to cracks or breaks. This excellent ductility allows them to adapt to various shapes and sizes in beverage can production, providing greater flexibility and diversity in production.

Beverage cans are one of the indispensable containers in our daily lives, carrying a variety of beverages, from soda to juice to beer. One of the main materials of beverage cans is 3104 3004 aluminum alloy. In the manufacturing process of beverage cans, the selection of suitable aluminum coil strips is crucial to the quality and performance of the product.

3004 and 3104 aluminum alloys are commonly used materials for beverage cans. They belong to the aluminum-manganese alloy series and have good formability, corrosion resistance and weldability. These properties are particularly important when making tanks.

3004 3104 aluminum coil strip specifications for can body

| Alloy for can body | 3004, 3104 |

| 3004 3104 aluminum coil with temper | H14, H19 |

| 3004 3104 aluminum coil strip thickness | 0.265-0.38mm±0.005mm |

| 3004 3104 aluminum coil strip width | 750-2400mm |

| 3004 3104 aluminum coil inner diameter | 405mm |

| 3004 3104 aluminum coil strip standard | EN 541, EN 573-3, YS/T435-2009, GB/T 3190, GB/T3880.1-2006 |

3004 3104 H19 Aluminum Coil Strip for Can Body Chemical Composition

3004 and 3104 aluminum alloys are commonly used materials for beverage cans. They belong to the aluminum-manganese alloy series and have good formability, corrosion resistance and weldability. These properties are particularly important when making tanks.

3004 aluminum alloy

Contains about 1% magnesium and about 0.8% silicon, with small amounts of copper and manganese.

It is suitable for deep drawing forming and welding, has high strength and corrosion resistance, and is often used in the manufacture of beverage cans.

| Element | Chemical composition (%) |

| 3004 | |

| Si | 0.3 |

| Fe | 0.7 |

| Cu | 0.25 |

| Mn | 1.3 |

| Mg | - |

| Cr | - |

| Zn | 0.25 |

| Ti | - |

| Al | Reminder |

3104 aluminum alloy

Contains about 0.8% magnesium and about 0.4% silicon, with small amounts of copper and manganese.

It has good formability and weldability, is suitable for various molding processes, and is often used to make beverage cans.

| Element | Chemical composition (%) |

| 3104 | |

| Si | 0.6 |

| Fe | 0.8 |

| Cu | 0.05-0.25 |

| Mn | 0.8-1.4 |

| Mg | 0.8-1.3 |

| Cr | - |

| Zn | 0.25 |

| Ti | 0.1 |

| Al | Reminder |

Physical properties of 3004 3104 can body aluminum coil strips

| Alloy | 3004 | 3104 |

| Temper | H19 | |

| Thickness/mm | 0.265-0.38 | |

| Tensile Strength Rm/MPa | ≥275 | ≥290 |

| Elongation at Break A50mm (%) | ≥255 | ≥270 |

| Elongation at Break A100mm (%) | ≥5 | |

| Earing Rate (%) | ≥3 | |

3004 3104 H19 Aluminum Coil Strip for Can Body Features

When making beverage cans, 3104 3004 aluminum coil strips usually need to be used in different states. The H19 status is one of them and has the following characteristics:

- 1. High strength: In H19 state, 3104 3004 aluminum coil strip has high strength and can withstand the stretching and forming processes during the production process.

- 2. Excellent formability: Aluminum coil strips still have good formability in the H19 state, which is beneficial to the production of tanks with complex shapes.

- 3. Stable thickness control: In the H19 state, the thickness control of 3004 3104 aluminum coil strip is more precise, which can ensure that the thickness tolerance of the tank is within a smaller range, which is beneficial to subsequent processing and the stability of product quality.

- 4. Corrosion resistance: Magnesium and manganese elements are added to 3104 3004 H19 aluminum coils to enhance its anti-oxidation and corrosion resistance. There is no need to pre-treat the inner and outer walls of the aluminum can. This makes them ideal for liquid beverage packaging, requiring only standard aluminum coatings/oils.

Exterior quality for 3004 3104 aluminum coil strips for can body

In order to ensure the quality and performance of beverage cans, it is crucial to strictly control the quality of aluminum coil strips. During the production process, the following aspects need to be strictly controlled:

- 1. Thickness control: Ensure that the thickness of the aluminum coil strip is controlled within the specified range to ensure the stability of subsequent processing and product consistency.

- 2. Flatness: The aluminum coil strip is not allowed to have obvious waves and requires high flatness, which is beneficial to subsequent processing.

- 3. Side curvature: Control the side curvature of the product within the specified range to ensure the appearance quality of the product.

- 4. Terminal warpage: Strictly control the terminal warpage height of the product to ensure the assembly quality and stability of the product.

Surface quality: Bubbles, paint leakage, scratches and other defects are not allowed on the surface of aluminum coil strips to ensure the appearance quality of the product.