5182 aluminum alloy is the most representative material for pull tab manufacturing. 5182 aluminum plate belongs to the 5xxx series aluminum-magnesium anti-rust alloy, with a magnesium (Mg) content of 4% to 5%. They offer excellent corrosion resistance and processability as well as high tensile strength, making them ideal for the production of aluminum pull tabs with specific hardness requirements.

Pull tabs mainly use 5182 alloy because it has a relatively high magnesium content compared to 5052 alloy, and a small amount of silicon is added, so the weldability is better than 5052 alloy.

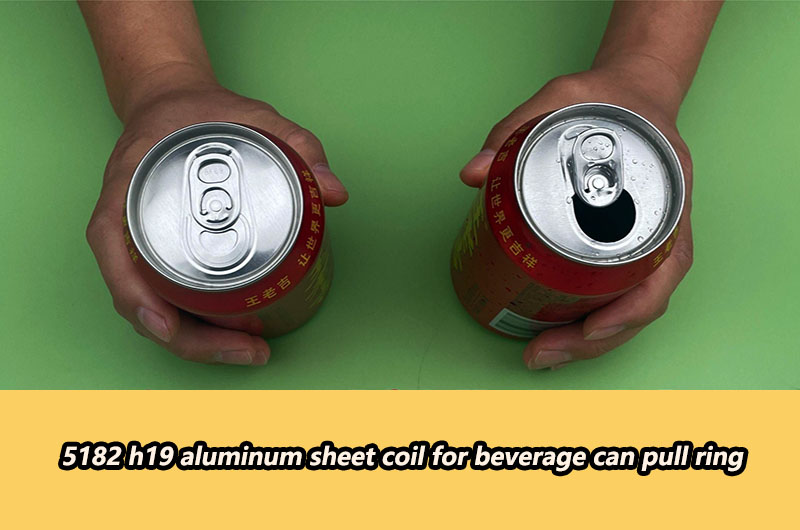

5182-H19 aluminum plate coil is the main alloy on the pull ring material, and the bottom of the tank is mainly 3004, 5052, etc. These alloys are not only used to make all-aluminum cans, but are also widely used to make tinplate cans and other packaging containers. With the development of the beverage industry and the replacement of old packaging materials, 5182 aluminum alloy will usher in greater applications in the packaging market.

Aluminum alloys are known for their lightweight, corrosion resistance and formability, making them ideal for numerous applications across a variety of industries. Within this range, the 5182 H19 aluminum alloy stands out for its specific properties that are tailor-made for can pull tabs.

5182 indicates the alloy composition, which consists mainly of aluminum, magnesium and manganese, as well as trace elements that contribute to its mechanical properties. The "-H19" temper designation indicates that the material has been strain hardened and finally annealed to achieve optimal strength and formability, which are essential properties for pull tab production.

The can lid is made of 5182/5052/3104 aluminum coil and different alloys, and the pull ring is made of 5182 H19 aluminum coil material.

Advantages of 5182 h19 aluminum plate coil for can end

- 1. Good anti-rust performance and wide range of uses.

- 2. Contains a small amount of Si, has excellent welding performance and low tendency to crack during welding.

- 3. Excellent corrosion resistance, high tensile strength and high yield strength.

- 4. The aluminum plates produced have no defects on the surface and are of high quality.

5182 h19 Aluminum coil for cans end product specifications

| Alloy type | 5182 H19 H48 |

| Thickness | 0.254-0.508mm |

| Width | Customized |

| UTS (MPa) | 320-420 |

| TYS (MPa) | 320-370 |

| Coating | PPG, Valspar, etc |

| Standard | EN, GB |

| Applications | Aluminium can tab |

Haomei Aluminum is a supplier of 5052 5182 aluminum coils. Our equipment includes flat ingot casting system, 2560mm "1+4" hot rolling production line, single stand and continuous rolling cold rolling production line, 2300mm tension leveling machine, 2300mm slitting/slitting machine , coating production line.

5182 h19 Aluminum coil forming and manufacturing for cans end

The versatility of 5182 H19 aluminum extends to its formability, enabling complex forming processes critical to tab production. Advanced stamping technology transforms flat aluminum coils into precisely contoured tab blanks with consistent dimensions and mechanical properties. In operation, precision is critical to ensure seamless integration with the tank lid while maintaining structural integrity and ease of use.

Corrosion resistance and surface treatment

One of the most important considerations for beverage packaging is maintaining product quality by preventing corrosion and contamination. The inherent corrosion resistance of 5182 H19 aluminum acts as a strong barrier against external elements, protecting the contents of the tank from adulteration or spoilage. To enhance this inherent property, aluminum panels are given advanced surface treatments such as organic coatings or varnishes before the tabs are formed.

These coatings not only enhance corrosion resistance, but also facilitate printing of brand elements, nutritional information or promotional graphics, adding aesthetic appeal and functional value to the final product.

5182 H19 Aluminum coil for the can end and pull tab performance

1. Material properties

5182 alloy: 5182 alloy is a member of the aluminum-magnesium alloy series, containing magnesium and a small amount of manganese and chromium. This alloy has good corrosion resistance, strength and weldability, making it suitable for making beverage can lids.

H19 status: The H19 status indicates that the processed alloy has high strength and hardness and is suitable for processing processes such as deep drawing and forming.

2. Deep drawing ability

5182 H19 aluminum coil has excellent deep drawing capabilities and can withstand high-frequency stamping without being prone to cracks or deformation. This makes it an ideal choice for making beverage can lids, which can meet the complex shape requirements of the can lids during the molding process.

3. Flatness and surface quality

The surface of 5182 H19 aluminum coil is highly flat and is not prone to waves and unevenness. At the same time, its surface quality has been carefully processed, and defects such as bubbles, paint leakage, and scratches are not allowed to occur, ensuring the appearance quality of the final product.

4. Processing performance

5182 H19 aluminum coil has good processing properties, including cold forming, cutting and welding. This makes the process of making beverage can lids smoother and more efficient.

5. Corrosion resistance

Due to the excellent corrosion resistance of 5182 alloy, the beverage can lids produced are not easily affected by the external environment and can keep the beverage inside the can fresh and hygienic.

6. Environmental protection

5182 H19 aluminum coil is a recyclable material and meets environmental protection requirements. It can be recycled and reused after use, reducing resource waste and environmental pollution.

As a material for beverage can lids, 5182 H19 aluminum coil has excellent deep drawing ability, flatness and corrosion resistance. It also has good processing performance and environmental protection, and can meet various requirements during the manufacturing and use of beverage can lids. , ensuring the quality and safety of beverage cans.

Chemical Property of 5052 5182 5082 H19 aluminum coil for ring pull end

| Alloy | 5052 | 5082 | 5182 |

| Cu | 0.1 | 0.15 | 0.15 |

| Si | 0.25 | 0.2 | 0.2 |

| Fe | 0.4 | 0.35 | 0.35 |

| Mn | 0.1 | 0.15 | 0.20-0.50 |

| Mg | 2.2-2.8 | 4.0-5.0 | 3.0-4.0 |

| Zn | 0.1 | 0.25 | 0.25 |

| Cr | 0.15-0.35 | 0.15 | 0.1 |

| Ti | 0.1 | 0.1 | |

| Al | Remainder | Remainder | Remainder |

5182 H19 Aluminum coil for the can end and pull tab mechanical properties

The mechanical properties of 5182 H19 aluminum alloy are carefully tuned to meet the stringent requirements of pull tab functionality. Its high tensile strength ensures beverage cans open and close reliably, withstanding repeated stress without compromising integrity. Additionally, the alloy's ductility allows for precise molding of complex tab designs, adapting to changes in can lid geometry while maintaining consistent performance. Enhanced elongation properties reduce the risk of breakage or deformation during manufacturing or handling, ensuring a perfect consumer experience every time you pull.

Pull tabs made from 5182 H19 aluminum contribute to the circular economy as they can be efficiently recycled, melted down and reincorporated into the production cycle with minimal loss of quality or performance. This inherent recyclability aligns with the principles of sustainable packaging, providing a viable alternative to single-use plastics and other non-renewable materials.

| Alloy | 5182 | 5182 | 5182 | |||

| Temper | H36, H46 | H18, H38, H48 | H19, H39, H49 | |||

| Thickness/mm | >0.220 -0.300 | >0.300 -0.500 | >0.220 -0.300 | >0.300-0.500 | >0.220-0.300 | >0.300 -0.500 |

| Tensile Strength Rm/MPa | 265 ~340 | 265 ~340 | 330 | ≥330 | ≥340 | ≥340 |

| Tensile Strength/MPa | ≥270 | ≥270 | ≥285 | ≥285 | ≥295 | ≥295 |

| Elongation % | ≥3 | ≥4 | ≥3 | ≥4 | ≥3 | ≥4 |

5182 h19 Aluminum coil application for cans end

The widespread adoption of 5182 H19 aluminum in the manufacture of can pull tabs highlights its indispensable role in the beverage packaging industry. From carbonated soft drinks to energy drinks, beer and more, aluminum pull tabs adorn a range of beverage cans around the world, providing consumers with unparalleled convenience and safety.

5182 H19 Aluminum Coil Offers Superior Performance and Versatility From its carefully crafted composition to advanced manufacturing processes, surface treatments and environmental sustainability, 5182 H19 aluminum embodies excellence in materials science and engineering. As beverage consumption patterns evolve and sustainability requirements become increasingly prominent, the role of aluminum tabs, and by extension 5182 H19 alloy, remains critical in shaping the future of packaging innovation and consumer experience.

Haomei Aluminum has rich experience in producing 5182 aluminum plate coils for can lid pull tabs. The product performance is stable and the quality is reliable, and it can be customized according to the actual needs of users.

Haomei Aluminum is a large-scale aluminum plate and coil manufacturer. It has cooperated with many large companies to supply can pull ring materials and can lid materials on a large scale for a long time.

Quality requirements for 5182 h19 aluminum coils for can lid pull tabs

- 1. Chemical composition and mechanical properties: Ensure that the chemical composition of aluminum alloy meets standards to ensure the reliability of its performance and use. In addition, mechanical properties such as tensile strength, yield strength and elongation must also be considered to meet the needs of manufacturing and use.

- 2. Surface quality: Ensure that the surface of the aluminum plate roll is smooth, clean, and free of scratches, dents or other defects to ensure that the product appearance and functionality are intact.

- 3. Dimensions and tolerances: The thickness, width and length of aluminum plate rolls should meet the specified dimensional requirements and remain stable within the tolerance range to ensure that the produced pull tabs are accurate in size.

- 4. Packaging and labeling: Products need to be properly packaged to prevent damage during transportation and storage, and should be marked with clear product information and warning labels.

- 5. Other special requirements: Depending on the specific application and customer needs, additional special requirements may need to be considered, such as specific surface treatment or corrosion resistance, to ensure that the overall performance of the product meets the expected standards.