8011 H16 aluminum alloy is a common aluminum alloy widely used in the manufacture of bottle caps and other packaging materials. The H16 temper indicates that the material has undergone 6/10 of cold working hardening, giving it moderate strength and good processing performance, making it ideal for applications such as pull-off caps.

8011 H16 indicates that the aluminum has undergone strain hardening and partial annealing. This achieves a balance between strength and ductility, making it suitable for various applications, including caps and seals.

The thickness of 8011 aluminum commonly used for pull-off caps may vary, but it is generally thin enough to be easily removed while still providing structural integrity.

8011 H16 Aluminum Alloy Characteristics

- 1. Alloy Composition: 8011 aluminum belongs to the aluminum-iron-silicon alloy, with iron and silicon as the main added elements. This gives it good strength and corrosion resistance.

- 2. Corrosion Resistance: This aluminum alloy has strong corrosion resistance, especially in humid environments, which is important for bottle cap materials to protect the contents from external environmental influences.

- 3. Formability: 8011 H16 aluminum alloy has good forming properties and can be made into various shapes of bottle caps through stamping and drawing processes. In the drawing process, the aluminum's ductility ensures that the cap retains good structural integrity when subjected to appropriate pressure.

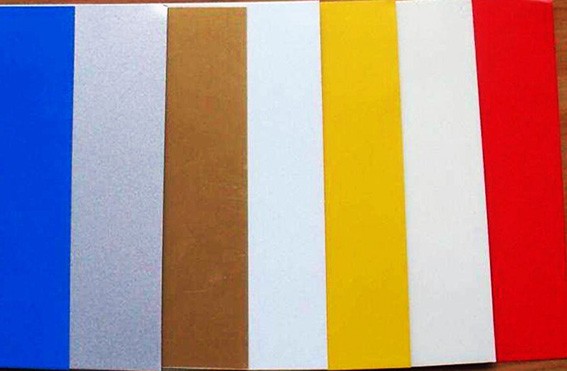

- 4. Surface Treatment: The surface of 8011 H16 aluminum alloy can undergo various treatments, such as color coating, DOS oil lubrication, chrome plating, or epoxy coating. These treatments can enhance the durability, aesthetics, and provide an extra protective layer for the aluminum caps.

- 5. Heat Resistance: It can withstand a range of temperatures, making it suitable for products exposed to varying conditions.

- 6. Barrier Properties: Aluminum effectively blocks light, moisture, and gases, helping maintain the integrity of the internal product.

Applications of 8011 H16 Aluminum in Pull-Off Caps

- 1. Cosmetic Bottle Caps: Suitable for perfume bottle caps, cosmetic bottle caps, etc. These caps generally require aesthetics, lightness, and good sealing, all of which 8011 H16 aluminum possesses.

- 2. Medicine Bottle Caps: In pharmaceutical packaging, pull-off caps require high sealing and hygiene standards. The corrosion resistance and excellent sealing properties of 8011 H16 aluminum provide good protection for medicines.

- 3. Beverage Bottle Caps: Used for pull-off caps on wine bottles, beer bottles, and carbonated beverage bottles, these caps require strong impact resistance. 8011 H16 aluminum can withstand the external forces generated during sealing.

- 4. Food Container Caps: Such as milk powder cans and yogurt lids, these caps must be non-toxic and highly resistant to oxidation to ensure food safety and long-term preservation.

Advantages of 8011 Aluminum for Pull-Off Caps

- 1. Lightweight: The low density of aluminum makes the bottle caps lighter, reducing the overall packaging weight, which is especially suitable for mass production and transportation.

- 2. Environmental Friendliness: Aluminum is recyclable, and 8011 aluminum used in caps is not only durable but also aligns with modern environmental trends, reducing the carbon footprint.

- 3. Excellent Sealing: Bottle caps made from 8011 H16 aluminum alloy have good sealing properties, effectively blocking air and preserving the quality of the product.

8011 H16 aluminum alloy, with its corrosion resistance, formability, and adaptability to various surface treatments, plays a key role in the production of pull-off caps, widely used in the packaging of cosmetics, pharmaceuticals, beverages, and food industries.