Currently, most cosmetic bottle caps on the market are made of plastic or aluminum-plastic materials. Aluminum-plastic covers have better sealing performance and more beautiful appearance, and are the first choice for many high-end cosmetics. 1060/1070/8011 are the main sheets of aluminum foil used for cosmetic bottle caps.

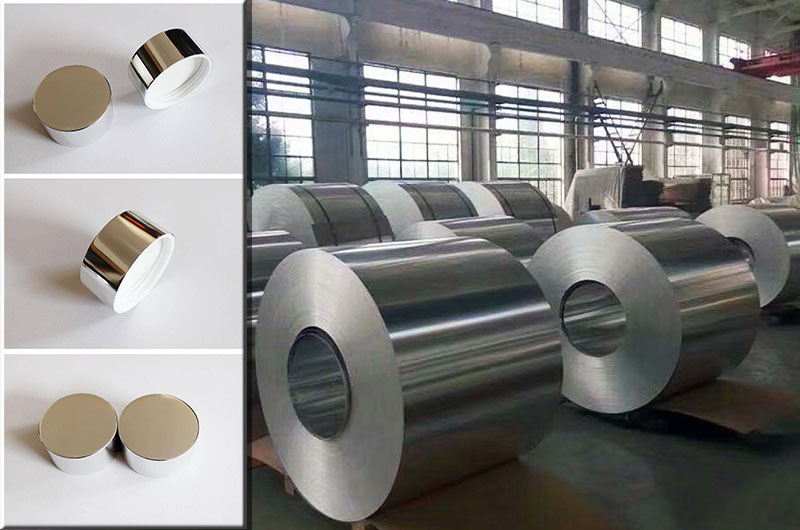

1060 1070 8011 Aluminum Sheet Coil Strip for Cosmetic Bottle Cap Aluminum sheet coil strip for cosmetic bottle caps has become a widely used material in the packaging industry due to its excellent performance.

Advantages of using 1060 1070 8011 aluminum sheet coil strip for cosmetic bottle caps

- 1. Lightweight and Durable: Aluminum is known for its lightweight, making it an ideal choice for bottle caps. The lightweight nature ensures ease of use and convenience for consumers while maintaining the durability needed to protect the contents of the bottle.

- 2. Corrosion resistance: Aluminum coils for cosmetic bottle caps are corrosion-resistant, ensuring that the bottle caps remain intact and functional even in humid environments or when exposed to various substances commonly found in cosmetics.

- 3. Hygiene and safety: Aluminum is non-toxic and will not interact with the contents of the bottle. It provides a barrier against contaminants, ensuring the safety of the product and maintaining its quality over the long term.

Aluminum sheet coil strip is the first choice for cosmetic bottle caps

Several aluminum alloys are commonly used to make cosmetic bottle caps, including 8011, 3104 and 5182. These alloys offer excellent formability, corrosion resistance and compatibility with a variety of coating technologies.

Cosmetic bottle cap material 1070 aluminum, 3105 aluminum material, 1060 aluminum foil, 3104 aluminum coil, 5052 aluminum coil, 8011 aluminum foil coil, what are the characteristics of each?

1070 aluminum sheet and strip for cosmetic bottle caps

Aluminum covers, aluminum alloy covers and decorative aluminum covers are usually made of 1070 aluminum alloy material. This aluminum alloy has excellent plasticity and processing properties and can be deeply processed to manufacture aluminum caps of various shapes and sizes.

- Alloy grade: 1070 aluminum alloy

- Status: H14, H24, H26, etc.

- Thickness range: usually 0.2 to 0.5mm

- Performance characteristics: easy to stretch, stable performance, smooth and delicate surface, tensile strength greater than 95.

High-end cosmetic bottle cap material 3105 aluminum sheet coil strp

Series 3 3105 aluminum alloy is mainly used in cosmetic bottle caps, and is also a good choice for high-end cosmetics. For example, our common lipsticks use aluminum alloy shells, and perfumes use aluminum alloy bottle caps. Aluminum bottle caps are widely used in product packaging because aluminum has good antioxidant properties and forms a dense layer on the surface of the aluminum. The oxide film protects the original physical properties of the product and has good sealing properties, ensuring that the product is not in contact with the outside world.

1060 aluminum sheet coil strip for cosmetic bottle caps

1060 aluminum foil has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. In production, Haomei Aluminum strictly controls the performance, plate shape, thickness difference and surface quality of aluminum foil rolls to obtain better product quality.

3104 aluminum sheet coil strip for cosmetic bottle caps

3104 aluminum coil is a deformed aluminum alloy with the characteristics of corrosion resistance, high tensile strength, good formability and excellent elongation. It is suitable for deep drawing to reduce the amount of material.

5052 aluminum sheet coil strip for cosmetic bottle caps

5052 aluminum coil is an Al-Mg alloy with good corrosion resistance, excellent weldability, good cold workability, and medium strength. It is widely used in bottle cap materials, lunch box materials, etc.

8011 aluminum sheet coil strip for cosmetic bottle caps

8011 aluminum foil has the advantages of clean surface oil removal, low lug rate, high cup convex value, high strength, and good sealing. The 8011 aluminum base material for bottle caps is widely used in bottle caps for wine, beverages, medical caps, cosmetics, etc. Packaging and other fields.

Characteristics of 1060 1070 8011 aluminum sheet coil for aluminum bottle caps

- 1. Aluminum foil used on bottle caps has excellent moisture-proof properties, light-shielding and high barrier capabilities, with uniform color and no spots, thereby ensuring the safety of cosmetics and extending the shelf life.

- 2. Aluminum foil rolls for bottle caps have good plasticity and can be used to package products of various shapes, and can also be formed into containers of various shapes.

- 3. The bottle cap material aluminum foil is tasteless and odorless, will not affect the use of cosmetics, has good recyclability, is safe and environmentally friendly.

Cosmetic bottle cap aluminum sheet surface treatment

- 1. Surface of ordinary precision-rolled aluminum strip

- 2. DOS oil lubrication treatment

- 3. Chrome plating

- 4. One side is gold/white/red/blue/black, and the other side is coated with protective paint

- 5. Double-sided varnish/transparent paint

Haomei Aluminum implements strict quality control on aluminum alloy materials, requiring smooth surfaces and no defects such as rolling marks, scratches, stains, etc. In addition, in order to meet the requirements of cosmetic packaging, the dimensional deviation and accuracy of the aluminum covers are strictly controlled to ensure that each product meets high quality standards.

Aluminum Sheet Coil for Cosmetic Bottle Cap Choose a reliable manufacturer

- 1. Experience and expertise: Look for manufacturers with extensive experience in the packaging industry. They should have an in-depth understanding of the specific requirements and standards for cosmetic bottle caps.

- 2. Quality Assurance: Ensure that manufacturers adhere to strict quality control measures throughout the entire production process. Certifications such as ISO 9001 guarantee their commitment to consistent quality.

- 3. Customization options: Consider whether the manufacturer can provide a custom solution to meet your unique requirements, such as different sizes, colors, or finishes.

Haomei Aluminum is a professional manufacturer of aluminum coils for bottle cap materials, which can produce aluminum coils of various specifications. Learn more about our reliable manufacturing services and how we can meet your specific cosmetic bottle cap aluminum coil sheet needs.

At present, cosmetic bottle caps on the market mostly use plastic materials and aluminum-plastic composite materials. In comparison, aluminum-plastic composite materials have better sealing performance and more beautiful caps. They are the choice of many high-end cosmetics. Plant bottle cap material. The aluminum-plastic bonded part of the aluminum-plastic composite bottle cap material will come into contact with the liquid in the bottle, so 1060 aluminum foil is often used as the aluminum foil base material for cosmetic bottle caps, and the thickness is generally between 0.17mm-0.5mm.

Haomei Aluminum has advanced production equipment and processing technology to ensure the processing quality and production efficiency of aluminum caps. Its cosmetic aluminum caps have excellent sealing performance, anti-leakage, lightweight and other characteristics, which can effectively protect the quality of cosmetics and extend the shelf life of products.