Aluminum is widely used in various caps and sealing applications in the pharmaceutical industry due to its excellent properties such as being lightweight, non-toxic, impermeable and recyclable.

Aluminum For Pharmaceutical bottle Caps come in many forms. The commonly used aluminum alloy oils for pharmaceutical bottles are 8011, 3105, and 1235.

Common application forms of Aluminum For Pharmaceutical bottle Caps include Aluminum Foil for Pharmaceutical Bottle Sealing, Aluminum Coil Strip for Pharmaceutical Vial Seal, and Aluminum Sheet Coil for Pharmaceutical Screw Caps.

Why choose Aluminum For Pharmaceutical bottle Caps?

1. Corrosion resistance

Aluminum has excellent corrosion resistance. This is particularly important in pharmaceutical applications, as it ensures that the cap is protected from chemicals and moisture in the drug product. Corrosion can compromise the integrity of the packaging, leading to contamination that renders the drug product ineffective and potentially dangerous.

2. Lightweight

Aluminum is lightweight and strong, making it ideal for pharmaceutical packaging as it adds minimal weight, reducing shipping costs. Lighter packaging also reduces transport emissions and reduces environmental impact.

3. ductility

Aluminum is highly malleable and easily formed into various shapes and sizes. Pharmaceutical bottle caps need to adapt to different container types and sealing requirements. Aluminum's malleability allows manufacturers to produce custom caps that provide the best seal for each drug product.

4. Recyclability

Aluminum is a highly sustainable material that is 100% recyclable without losing its inherent properties. This recyclability aligns with the pharmaceutical industry's focus on environmental responsibility and sustainability. Recycled aluminum reduces the need for virgin materials, conserves resources and lowers the carbon footprint of pharmaceutical packaging.

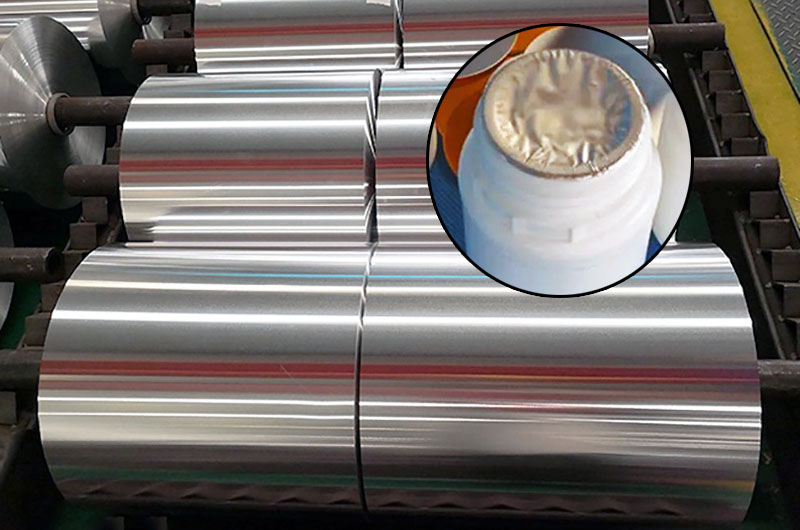

8011 1235 Aluminum Foil for Pharmaceutical Bottle Sealing

Aluminum foil is laminated with a polymer layer and used as an induction seal to seal the opening of the bottle. The foil is placed over the mouth of the bottle and sealed using an induction heating process.

Aluminum Foil for Pharmaceutical Bottle Sealing Advantages

- Seal Integrity: Creates an airtight seal to prevent contamination.

- Tamper Resistance: Provides visual indication of tampering.

- Barrier Properties: Protects contents from light, oxygen and moisture.

Aluminum Foil for Pharmaceutical Bottle Sealing Specifications

- Alloys used: 8011, 1235

- Status: H18, O (soft)

- Thickness: 0.02mm to 0.03mm (20 to 30 microns)

- Width: Customizable, usually 200mm to 1500mm

- Coating: Typically laminated with polyethylene (PE) or other polymers for sealing purposes

Aluminum Foil for Pharmaceutical Bottle Sealing Applications

- Sealing Liners: Used as internal seals on medication bottles to ensure evidence of tampering and protect the contents from contamination.

- Cap Seal: Commonly used as an induction seal for plastic or glass bottles, providing a secure and tamper-proof closure.

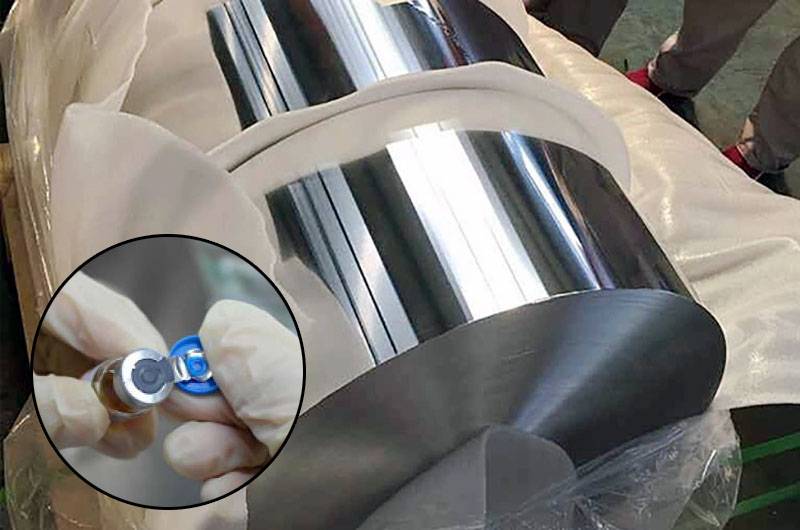

8011 h14 h16 Aluminum Coil Strip for Pharmaceutical Vial Seal

Vial Seals (Flip Seals): Used to secure rubber to vials containing injectable medications, these aluminum seals are used in conjunction with rubber stoppers, these aluminum seals provide additional security and safety of injectable products Tampering with evidence.

Aluminum Foil for Pharmaceutical Bottle Sealing Forms

- Crimp Caps: Made from aluminum coil strips that are shaped and crimped over the vial tops.

- Flip-Off Caps: Feature a plastic button on top of the aluminum seal for easy removal.

Aluminum Foil for Pharmaceutical Bottle Sealing Advantages

- Durability: Ensure vial remains sealed until opened.

- Sterility: Maintain sterility of vial contents.

- Security: Prevents unauthorized access to vial.

Aluminum Foil for Pharmaceutical Bottle Sealing Specifications

- Alloy used: 8011

- Status: H14, H16

- Thickness: 0.15mm to 0.25mm

- Width: 15mm to 100mm (depending on cap size)

- Surface treatment: can be plain, painted or printed

8011 3105 Aluminum Sheet Coil for Pharmaceutical Screw Caps

Screw caps are stamped and threaded from 8011 or 3105 aluminum sheet coils. Manufactured screw caps for medicine bottles that provide a secure, resealable closure.

Aluminum Sheet Coil for Pharmaceutical Screw Caps Advantages

- Resealability: Bottles can be safely resealed after every use.

- Strength: Provides a strong, durable closure.

- Customize: Easily embossed or printed with branding and instructions.

Aluminum Sheet Coil for Pharmaceutical Screw Caps Specifications

- Alloys used: 8011, 3105

- Status: H14, H16, H24

- Thickness: 0.20mm to 0.40mm

- Width: 50mm to 500mm

- Surface treatment: usually color coating or plain coating, depending on brand and requirements

Aluminum For Pharmaceutical Bottle Caps Advantages

1. Tamper-proof seal

The pharmaceutical industry takes product security and tamper resistance very seriously. Aluminum bottle caps provide a tamper-evident seal and must be removed before the bottle can be opened.

2. Barrier performance

Aluminum has excellent oxygen, moisture and light barrier properties. For pharmaceuticals that are sensitive to environmental factors, these factors need to be prevented from affecting their stability and efficacy. The aluminum cover acts as a reliable barrier, maintaining the quality of the product throughout its shelf life.

Acceptance standards before packaging of aluminum coils for medicinal bottle caps

- 1. The end surface of the roll should be clean and tidy, without cracks, burrs, warping, folding, burrs, unevenness, etc.

- 2. The misalignment of the entire roll is <2mm, and the tower shape is <5mm.

- 3. The strips unfold freely on the platform, with wave height <3mm; the number of waves within any one meter does not exceed 3

- 4. The surface should be smooth, clean, and free of oil spots, and no wrinkles or serious indentations are allowed.