3105 H14 Aluminum Coil Sheet for PP Caps

Last Updated :Nov. 08, 2024

3105 H14 aluminum coil is a commonly used alloy material for PP bottle cap production, particularly suitable for applications that require high strength, excellent processability, and good rust resistance. It is an aluminum-manganese alloy, typically containing 0.3% to 0.8% manganese, which provides outstanding corrosion resistance and weatherability. These characteristics make 3105 H14 aluminum coil ideal for use in bottle caps, especially in industries such as food, beverage, and cosmetics, where there are high demands on the quality and reliability of caps.

Characteristics of 3105 H14 Aluminum Plate

1. Excellent Corrosion Resistance

Thanks to the addition of manganese, 3105 aluminum alloy has excellent oxidation and corrosion resistance, effectively resisting acidic or alkaline components in the contents of the bottle. This is crucial in the production of PP bottle caps, particularly when packaging sensitive products such as beverages, alcoholic drinks, or cosmetics, ensuring the cap’s sealing performance and food safety.

2. Deep Drawing and Processability

The deep drawing performance of 3105 H14 aluminum plate is outstanding, making it suitable for precision bottle cap production. The H14 temper indicates a moderate degree of work-hardening, which increases the plate’s strength and rigidity without compromising its ductility. This ensures the shape accuracy and longevity of the aluminum cap. During the manufacturing process, the aluminum plate can be formed into various complex geometries through deep drawing, while maintaining its shape integrity.

3. Strength and Hardness

The H14 temper aluminum plate has higher strength compared to soft-temper aluminum plates, making it suitable for withstanding external forces during the sealing, transportation, and stacking processes of the bottle cap. The aluminum cap will not easily deform or get damaged during use.

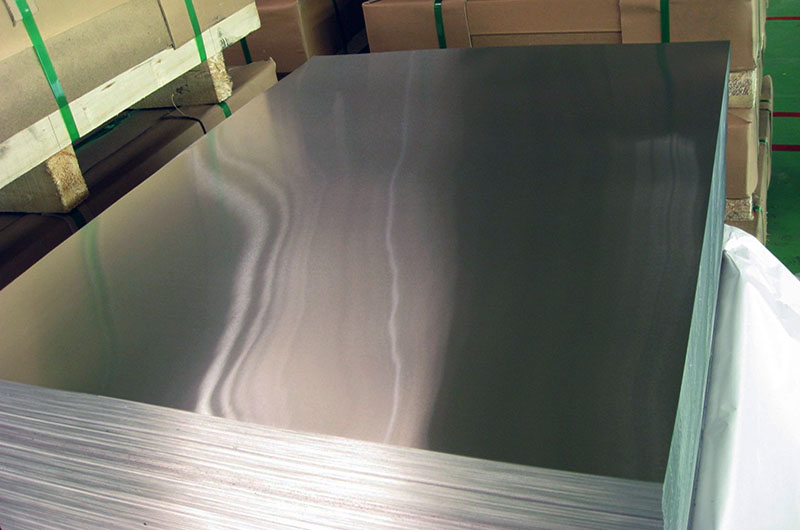

4. Excellent Surface Treatment Capability

The surface of 3105 H14 aluminum plate is smooth and suitable for various surface treatments such as color coating, printing, or plating. These treatments not only enhance the appearance of the aluminum cap but also provide an additional protective layer, making the cap more durable and resistant to damage or fading over time.

Application of 3105 H14 Aluminum Plate in PP Bottle Cap Production

In the production of PP bottle caps, 3105 H14 aluminum coil undergoes processes like cutting and stamping to form sturdy and elastic caps. Due to its excellent deep drawing capability, 3105 aluminum plate can meet the structural requirements of various bottle caps, such as screw caps and bottle mouth seals.

1. Bottle Cap Sealing Performance

3105 H14 aluminum caps effectively seal the bottle, preventing external air from entering and ensuring the quality and safety of the contents, thus extending the shelf life.

2. Lightweight and Durability

3105 aluminum alloy offers high strength and lightweight properties, reducing the weight of the bottle cap while maintaining its strength. This makes the cap both lightweight and sturdy without adding extra transportation burden.

3105 H14 aluminum plate meets environmental standards and can be recycled. Aluminum alloy has high recyclability, complying with increasingly strict global environmental regulations and reducing the environmental impact during the production process.

3105 H14 aluminum coil, with its excellent strength, deep drawing ability, corrosion resistance, and outstanding processability, is one of the key materials for PP bottle cap production. Whether for food packaging, beverage bottle caps, or cosmetic bottle caps, 3105 aluminum plate provides superior sealing, strength, and durability, ensuring long-term performance of the caps.

Other Applications of 3105 H14 Aluminum Plate

Apart from bottle cap manufacturing, 3105 aluminum plate can also be used in a variety of applications such as room partitions, color-coated aluminum base plates, cans, lamp holders, blinds, bottle stoppers, kitchen utensils, and food and chemical processing and storage equipment.