The Role of 8011 3105 Painted Aluminium Strip in Food and Beverage Packaging

Last Updated :Jan. 10, 2025

8011 aluminum strip offers high strength, corrosion resistance, and formability, making it widely used in food packaging and bottle caps. 3105 aluminum strip, on the other hand, is commonly used for beverage can lids and flexible packaging due to its excellent corrosion resistance and malleability.

Both 8011 and 3105 painted aluminum strips are widely used in the food and beverage packaging industry due to their outstanding mechanical properties, corrosion resistance, and aesthetic appeal.

Painted 8011 and 3105 aluminum strips play a key role in enhancing the quality, safety, and aesthetic appeal of food and beverage packaging. Their combination of strength, corrosion resistance, and surface properties makes them ideal materials for widespread applications, ensuring that products remain fresh, protected, and attractive to consumers.

Advantages of Painted 8011 and 3105 Aluminum Strips in Food and Beverage Packaging

- Barrier Protection: Both 8011 and 3105 aluminum strips provide excellent moisture, oxygen, and light barriers, which are key factors in extending the shelf life of food and beverage products.

- Branding and Aesthetics: The smooth surface of painted aluminum strips is printable, allowing for vibrant, clear branding, product information, and decorative designs that attract consumer attention and convey product quality.

- Sustainability: Aluminum is a highly recyclable material, making it an eco-friendly choice for packaging. Using aluminum strips can reduce the carbon footprint, especially when using post-consumer recycled materials.

- Consumer Convenience: Both 8011 and 3105 aluminum strips are used for packaging that offers consumer-friendly features, such as easy-pull tabs and resealable lids, enhancing convenience and product usability.

Detailed Comparison Table of 8011 Aluminum Strip and 3105 Aluminum Strip in Food and Beverage Packaging

| Properties | 8011 Aluminum Strip | 3105 Aluminum Strip |

| Strength | High tensile strength, suitable for thin and flexible foil and sealing materials | Moderate strength, suitable for lightweight and durable packaging materials |

| Formability | Easily stamped, rolled, or molded into various packaging forms | Highly malleable, can form complex shapes like bottle caps, seals, etc. |

| Lightweight | Light in weight, reduces transportation and storage costs | Lightweight, suitable for applications requiring light but durable packaging |

| Corrosion Resistance | Excellent oxidation resistance and corrosion resistance, protecting food and beverages from contamination | Outstanding corrosion resistance, especially in acidic environments, ensuring long-term degradation-free packaging |

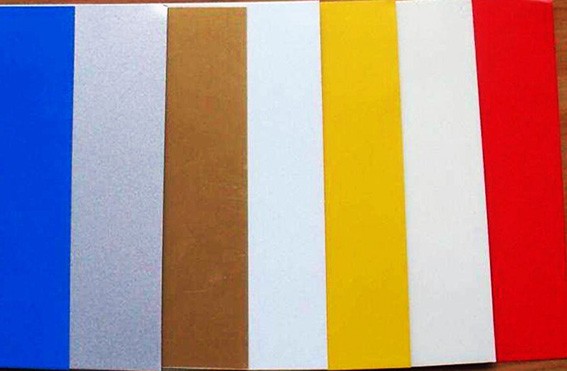

| Painted Surface | Often coated with varnish or coating, enhancing aesthetics and protection from environmental factors | Coated or painted surface, enhancing aesthetics and protecting the aluminum from degradation |

| Printability | Smooth painted surface suitable for high-quality branding and nutritional information printing | Also printable, suitable for brand printing and food information display |

| Functional Coatings | Can be used in food packaging without reacting with food, providing a protective barrier | Uses food-grade coatings to ensure no harmful chemicals are leached |

| Foil | Used in food packaging, small bags, and container linings, providing good barrier properties | Not commonly used for foil packaging but can be used in other forms of packaging |

| Beverage Can Lids and Bottle Caps | Used for carbonated and non-carbonated beverage can lids, providing airtight sealing | Used for beverage can lids and soda, juice bottle caps, providing corrosion-resistant sealing |

| Beverage Packaging | Commonly used in beverage can lids and bottle caps to prevent contamination and gas loss | Suitable for beverage can sealing systems, ensuring long-term freshness and leak protection |

| Flexible Packaging | Not commonly used in flexible packaging but can be used for laminated sheets and small packaging containers | Commonly used in snack and other food packaging bags, providing lightweight protection and barrier properties |

| Lids and Seals | Used in food can lids, easy-open seals, etc. | Used in food can lids, easy-open seals, and pull-tab ends |

8011 aluminum strip, with its high strength and corrosion resistance, is widely used in food packaging, beverage bottle caps, and aluminum foil, effectively extending the shelf life of food and ensuring that the packaged items are not contaminated.

3105 aluminum strip is known for its excellent corrosion resistance and formability, making it especially suitable for beverage can lids, bottle caps, and food can lids. Additionally, its coating effectively protects food from harmful contaminants.

Food and Beverage Packaging Aluminum Strip 8011

8011 aluminum alloy is well-known for its high strength, good corrosion resistance, and formability, making it an ideal choice for packaging applications. In food and beverage packaging, 8011 aluminum is commonly used to produce aluminum foil, bottle caps, and laminate sheets.

8011 Aluminum Strip Mechanical Properties

- Strength: 8011 aluminum has high tensile strength, allowing it to be made into thin, flexible foil without sacrificing structural integrity. This is especially important in packaging applications that require tight sealing and protection for food and beverages.

- Formability: It can be easily stamped, rolled, or shaped into various packaging forms such as pouches, caps, and wrapping paper.

- Lightweight: 8011 is lightweight, which reduces the overall weight of the packaging material, improving storage and transportation efficiency.

8011 Aluminum Strip Corrosion Resistance

The inherent corrosion resistance of aluminum ensures that food and beverage products are protected from external contaminants. 8011 aluminum also has antioxidant properties, helping to maintain the flavor and quality of the packaged items.

8011 Aluminum Strip Surface Properties

- Coated Surface: 8011 aluminum is often coated with various coatings, including varnish or paint, to create a barrier that enhances its appearance and protects it from environmental factors. This makes it an ideal choice for printed packaging such as labels and decorative designs.

- Printability: The smooth coated surface allows for high-quality printing, making it suitable for brand logos, nutritional information, and other consumer-facing details.

8011 Aluminum Strip in Food and Beverage Packaging

Aluminum Foil: 8011 is commonly used in food packaging, small pouches, and container liners. Its ability to block light, oxygen, and moisture is crucial for maintaining the shelf life of perishable foods such as snacks, chocolates, and ready-to-eat foods.

Beverage Can Lids and Can Lids: 8011 aluminum is used to produce beverage can lids and can lids for both carbonated and non-carbonated drinks, providing an airtight seal to prevent contamination and carbonation loss.

Food and Beverage Packaging Aluminum Strip 3105

3105 aluminum alloy is known for its excellent corrosion resistance and formability, making it particularly suitable for food and beverage packaging applications that require materials to withstand environmental factors such as humidity and exposure to food acids.

3105 Aluminum Strip Mechanical Properties

- Good Strength-to-Weight Ratio: 3105 aluminum has moderate strength, making it ideal for applications where the material needs to be lightweight yet durable. It can withstand the stresses of transportation, handling, and storage.

- Malleability: This alloy has high malleability, allowing it to be formed into complex shapes for packaging designs such as bottle caps, seals, and flexible packaging materials.

3105 Aluminum Strip Corrosion Resistance

3105 aluminum has excellent corrosion resistance, particularly in acidic environments generated by beverages, ensuring that the packaging does not degrade over time, which is crucial for maintaining the quality of the internal product.

3105 Aluminum Strip Surface Properties

- Coatings and Coatings: Similar to 8011, 3105 is often used with coated or coated surfaces to provide a protective layer and aesthetically pleasing, printable appearance. These coatings protect the aluminum from degradation while enhancing its visual appeal with a bright, glossy surface.

- Decorative and Functional Coatings: For food and beverage packaging, 3105 aluminum is often used with coatings that meet food-grade requirements. This ensures that the product does not release harmful chemicals into the food or beverage.

3105 Aluminum Strip in Food and Beverage Packaging

- Beverage Cans: 3105 is commonly used in beverage cans and soda and juice can lids. Its formability and corrosion resistance make it an ideal choice for these applications, providing a durable, secure seal.

- Lids and Seals: 3105 aluminum is used in food can lids, easy-open seals, and pull-tab ends. The alloy’s corrosion resistance ensures that these closures maintain their integrity over time, preventing leaks or contamination.

- Flexible Packaging: 3105 aluminum strip is also used to produce packaging bags and pouches for snacks and other packaged foods, providing lightweight protection and barrier properties.