Why 8011 and 3105 Lacquered Aluminium Are Ideal for Medicine and Wine Bottle Caps

Last Updated :Dec. 13, 2024

8011 and 3105 aluminum alloys are commonly used for making painted bottle caps, especially in the pharmaceutical and wine industries. These alloys have several key properties that make them particularly suitable for these applications, where hygiene, reliability, and content protection are crucial.

Material Properties of 8011 and 3105 Aluminum

- Strength and Durability: 8011 is a high-strength alloy, making it an ideal choice for bottle caps that must withstand pressure and impact during transportation and handling.

- Corrosion Resistance: It has excellent corrosion resistance, which is essential for maintaining the integrity of contents, whether pharmaceuticals or premium wine. This alloy resists moisture, oils, and various chemicals, ensuring that the cap won't degrade over time.

- Formability: 8011 aluminum has good formability, making it suitable for forming thin and precise layers that can be easily shaped into bottle caps without cracking or breaking.

- Surface Quality: It has a smooth, clean surface, which is perfect for painting. This quality ensures that the coating adheres effectively and uniformly, creating a protective layer that is both aesthetically pleasing and functional.

- Moderate Strength and Excellent Corrosion Resistance: While 3105 is not as strong as 8011, it still offers moderate strength and excellent corrosion resistance. This is critical for pharmaceutical and wine bottle caps, which need to ensure a tight seal without deterioration, especially in humid environments.

- Formability and Ease of Processing: 3105 aluminum has high ductility, making it easy to process into thin sheets. This is particularly important for manufacturing complex bottle cap designs or features (such as pull tabs or tamper-evident seals).

- Lightweight: This alloy is lightweight, helping to reduce the overall weight of the bottle while still maintaining sufficient strength to seal and protect the contents.

Benefits of the Painted Coating

The painted coating process plays a crucial role in enhancing the performance of 8011 and 3105 aluminum alloys.

Protection from Environmental Factors

The painted coating provides an additional layer of protection, preventing the aluminum from being affected by UV rays, oxygen, or chemicals. This is particularly important for maintaining the flavor and quality of wine or the potency and safety of pharmaceuticals.

The coating also ensures that the aluminum does not react with the contents of the bottle. For example, certain drugs and wine varieties are highly sensitive to metals, and the coating forms a barrier that prevents any unwanted chemical reactions.

Prevention of Contamination

The painted coating helps maintain a hygienic seal, ensuring that the contents of pharmaceutical or wine bottles remain uncontaminated. This is crucial in the pharmaceutical industry, as product integrity is a regulatory requirement.

It also acts as a barrier to prevent bacterial growth or other microbial issues, which is especially important in the pharmaceutical industry.

Aesthetic Appeal

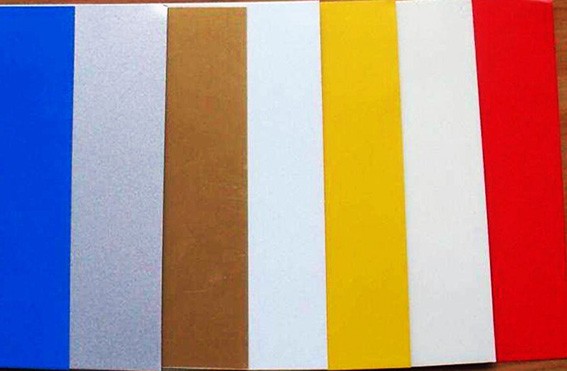

The painted finish provides a glossy, smooth, and attractive appearance. For wine bottles, visual appeal is an important factor for branding and consumer perception. A beautifully painted cap also reflects premium quality, which is why it is widely used in the wine industry.

In pharmaceutical packaging, the painted finish can feature labels, logos, or other information, providing a clear and attractive look.

Advantages of 8011 and 3105 Aluminum Alloys for Painted Pharmaceutical Bottle Caps

- Tamper-Evident Feature: Both alloys can be easily manufactured to include tamper-evident features, such as seals or breakable bands. This ensures the bottle has not been opened or tampered with, which is vital for the safety and authenticity of pharmaceuticals.

- Non-Toxic: Both 8011 and 3105 alloys are non-toxic and safe for use in the pharmaceutical industry. The paint used is specially selected to ensure that no harmful chemicals leach into the medication.

- Sterilization Compatibility: Pharmaceutical bottle caps often require sterilization to ensure safe use in medical environments. Painted aluminum alloys perform well under sterilization processes, such as autoclaving or gamma radiation, which are commonly used for medical packaging.

Advantages of 8011 and 3105 Aluminum Alloys for Painted Wine Bottle Caps

- Sealing Performance: The painted aluminum caps provide a reliable and tight seal, preventing oxidation and preserving the quality of the wine. The secure seal also prevents leaks and maintains the integrity of the contents.

- Extended Shelf Life: Wine bottles sealed with painted 8011 or 3105 aluminum caps can maintain the taste and aroma of the wine for longer periods. UV and oxygen barriers ensure that the wine’s flavor is unaffected, especially for bottles intended for long-term aging.

- Premium Appearance: The glossy painted finish enhances the visual appeal of the bottle, which is an important factor in wine marketing. It creates a high-end look that aligns with premium brands, giving consumers a sense of luxury.

Both 8011 and 3105 painted aluminum alloys offer excellent corrosion resistance, formability, strength, and aesthetic appeal, making them ideal for pharmaceutical and wine bottle caps. The painted coating provides a critical protective layer against environmental factors, contamination, and tampering.