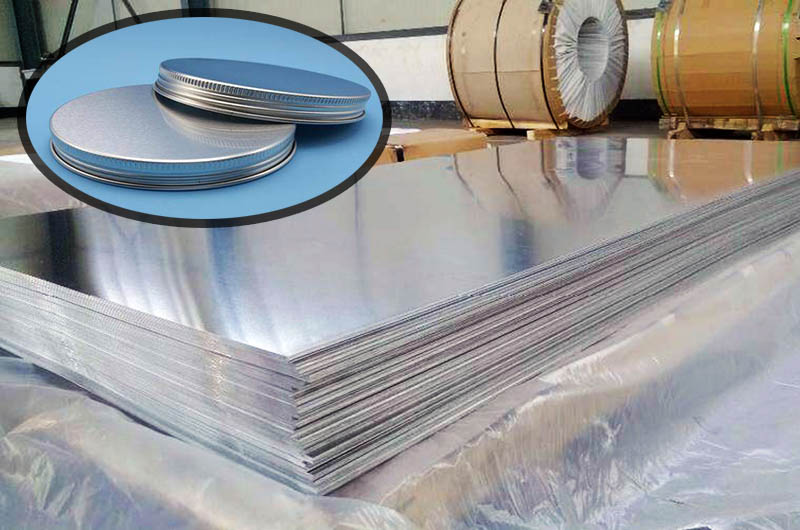

8011 h14 h16 aluminum sheet for jar cap

Last Updated :Apr. 10, 2024

In packaging, especially in the food and beverage industry, can lids play a vital role in preserving freshness, ensuring safety and enhancing shelf appeal. Among the materials used for the manufacture of can lids, aluminum stands out for its excellent properties such as lightness, corrosion resistance and formability.

8011 is a deformed aluminum alloy with silicon and iron as the main alloy elements. The H14 and H16 temper designations indicate specific treatments performed on the alloy that affect its mechanical properties and formability. In the H14 temper, the aluminum is only strain hardened, while in the H16 temper, the aluminum is strain hardened and partially annealed. These tempering conditions increase strength and formability, making the alloy suitable for complex forming processes in can lid manufacturing.

Advantages of 8011 H14 H16 aluminum can lids

- 1. Sustainability: Aluminum is highly recyclable and has a significantly lower environmental impact than alternative materials. Recycled aluminum retains its properties without degrading, promoting circularity and resource efficiency in the packaging supply chain.

- 2. Barrier properties: Aluminum can effectively block light, oxygen, moisture and other environmental factors, extend the shelf life of packaged products and maintain their sensory properties.

- 3. Customization options: Aluminum can lids offer ample opportunities for branding, labeling, and customization through embossing, printing, or surface treatment techniques. This allows for brand differentiation and increased product visibility on retail shelves.

8011 h14 h16 aluminum sheet for jar cap performance

- 1. Corrosion Resistance: Aluminum inherently has excellent corrosion resistance, especially in the form of aluminum oxide that forms a protective layer when exposed to oxygen. This feature ensures the longevity and integrity of the can lids, even under harsh storage conditions.

- 2. Lightweight: The density of aluminum is about one-third that of steel, which can significantly reduce weight without affecting strength. This lightweight property reduces shipping costs and increases handling efficiency, thereby contributing to the overall sustainability of the packaging operation.

- 3. Formability: 8011 H14 H16 aluminum alloy sheet has excellent formability, enabling complex designs and precise dimensions required for custom can lid configurations. Whether embossed, stamped or deep drawn, the material easily adapts to a variety of manufacturing processes, ensuring consistency and precision in final product specifications.

- 4. Thermal conductivity: Aluminum has excellent thermal conductivity, which is beneficial to rapid heat dissipation during the sealing process. This property is particularly advantageous in high-speed production lines, where efficient heat transfer is critical to achieving a tight seal and maintaining product freshness.

Size and deviations from the size

- Thickness tolerance -0+0.5mm

- Width tolerance -0+0.5mm

- Length tolerance -0+0.5mm

8011 h14 h16 aluminum sheet for jar cap sheet surface

The surface of the aluminum plate of the can cover should be free of oil, which is controlled by testing with a clean natural cotton pad dipped in 100% distilled water. The lay is smooth with no pauses from one end to the other. Oil-free grade: B, C or D.

Drops and spots on the surface of the sheet due to corrosion and burnt lubricants are unacceptable.

Minor scratches and stains are also unacceptable.

8011 h14 h16 aluminum sheet for jar cap surface type

- a. Flat ground aluminum plate for can cover

- b.DOS oil lubrication surface treatment

- c.Chromate treatment

- d. One side is gold/white/red/blue/black and other colors, and the other side is protective paint

- e.Double-sided varnish/transparent paint

8011 h14 h16 aluminum sheet chemicacomposition

| Alloy | 8011 | |

| Si | 0.4-0.8 | |

| Fe | 0.5-1.0 | |

| Cu | 0.1 | |

| Mn | 0.1 | |

| Mg | 0.1 | |

| Cr | 0.1 | |

| Ni | - | |

| Zn | 0.1 | |

| Ti | 0.05 | |

| Other | Each | 0.05 |

| Total | 0.15 | |

| Aluminum | Remainder | |

Mechanical data

- Stretch resistance Rm--Min 180 Mpa Max 220 Mpa

- Yield strength Rpop minimum 145Mpa

- Elongation minimum 2%

| Temper | H14 | H16 | ||

| Thickness mm | 0.20-0.27 | 0.20-0.27 | ||

| Tensile Strength | Rm MPa | min. | 120 | 160 |

| max. | 170 | |||

| Yield Strength | Rp0.2 MPa | min. | 110 | 145 |

| max. | ||||

| Elongation % | A50mm | 1 | 1 | |

| Bend Radius | 180° | |||

| 90° | ||||

| Hardness HBWa | 41 | 50 | ||

Manufacturing process

Producing bottle caps from 8011 H14 H16 aluminum sheet involves a series of specialized processes, each designed to optimize material properties and achieve the desired cap characteristics. These processes typically include:

- Rolling: The aluminum ingot is first heated and rolled into sheets of the desired thickness. Controlled rolling parameters ensure uniformity and precise thickness control, which is crucial for subsequent forming operations.

- Annealing: For the H16 state, the rolled plate is partially annealed to eliminate internal stress and improve formability while maintaining sufficient strength.

- Forming: Various forming techniques such as stamping, deep drawing and embossing are used to form the aluminum sheet into the required cover profile. Advanced tooling and mold design ensure high precision and repeatability throughout the molding process.

- Surface Treatment: Use surface treatments such as cleaning, coating, or painting to enhance corrosion resistance, improve aesthetics, and achieve compatibility with sealing liners.

- Quality Control: Strict quality control measures are implemented at every stage of production to ensure compliance with dimensional tolerances, mechanical properties and surface finish specifications. Non-destructive testing techniques such as visual inspection, ultrasonic testing and eddy current testing are used to detect any flaws or defects.

8011 H14 H16 Aluminum can lid applications

The versatility and reliability of 8011 H14 H16 aluminum plate make it ideal for a variety of can lid applications across a variety of industries:

- Food packaging: From sauces and condiments to jams and pickles, aluminum can lids provide a secure seal and are tamper-evident, ensuring product freshness and integrity.

- Beverage packaging: Aluminum can lids provide reliable sealing solutions for beverages such as juices, concentrates and syrups, preserving flavor and preventing contamination.

- Pharmaceutical Packaging: In pharmaceutical applications, aluminum can lids provide an airtight seal that protects the potency and efficacy of sensitive medications and supplements.

- Cosmetics and Personal Care Products: Aluminum can lids are widely used in the cosmetics and personal care industry to package creams, lotions, balms and ointments to maintain product quality and shelf appeal.