The Benefits of DOS Coated Aluminum Coil 3105 in Pilfer-Proof PP Cap Production

Last Updated :Jan. 24, 2025

DOS coated aluminum coil 3105 demonstrates numerous advantages in the production of pilfer-proof bottle caps, including excellent formability, outstanding surface treatment performance, enhanced corrosion resistance and sealing properties, as well as good environmental friendliness and cost-effectiveness. It meets the multiple demands of the pilfer-proof cap industry in terms of safety, functionality, quality, and cost, making it an ideal material for producing high-quality pilfer-proof bottle caps.

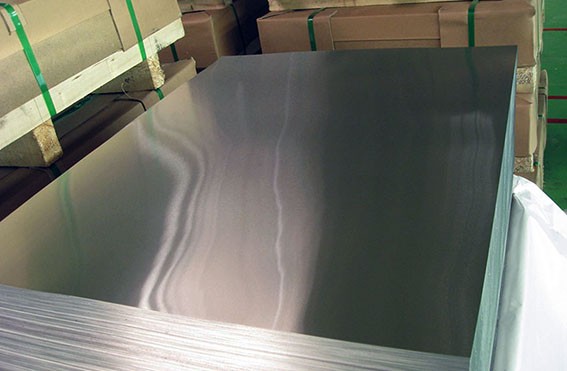

Haomei Aluminum DOS Coated Aluminum Coil 3105

| Property | Details |

| Model NO. | 3105 |

| Technique | Rolling |

| Grade | 3105 |

| Temper | O - H112 |

| Surface Treatment | Mill Finish |

| Alloy | Alloy |

| Transport Package | Export Standard |

| Specification | American Standard |

| Trademark | HM |

| Origin | China |

| Production Capacity | 4000mt/Month |

Advantages of Choosing DOS Coated Aluminum Coil 3105 for Pilfer-Proof PP Caps

Excellent Formability

DOS coated aluminum coil 3105 exhibits exceptional ductility and formability, making it particularly suitable for producing complex cap structures. Pilfer-proof bottle caps typically require precise stamping and deep drawing processes. The 3105 aluminum alloy meets these process requirements, ensuring precise cap formation while maintaining adequate strength and sealing performance.

Excellent Surface Treatment

The DOS coating (oil lubrication coating) provides additional lubrication to the 3105 aluminum alloy, effectively reducing friction between the aluminum material and tools during production. This helps avoid cracks or defects caused by excessive friction. This surface treatment not only improves production stability but also reduces tool wear, extending equipment lifespan and reducing production costs.

Enhanced Corrosion Resistance

Pilfer-proof bottle caps need to withstand the impact of external environments, especially contact with liquids such as beverages, pharmaceuticals, and chemicals. The DOS-coated 3105 aluminum alloy forms a protective film on the surface, effectively preventing oxidation and corrosion, maintaining the appearance and functionality of the caps. Even in humid or corrosive environments, this coating offers long-lasting protection, ensuring the cap’s stability over time.

High Strength and Durability

In the O-H112 temper, 3105 aluminum alloy offers good strength and durability, ensuring the cap remains stable during transportation, storage, and use, preventing deformation or damage. As pilfer-proof caps need to withstand certain pressures and external forces, the high strength of 3105 aluminum alloy helps maintain the integrity and reliability of the pilfer-proof function.

Good Sealing Performance

The surface of bottle caps made from DOS coated aluminum coil 3105 is smooth and uniform, minimizing gaps between the bottle neck and cap, ensuring excellent sealing performance. This effectively prevents air, moisture, and contaminants from entering the bottle, ensuring the safety of the contents, especially in preserving the freshness and effectiveness of liquids or pharmaceuticals.

Environmental Friendliness and Recyclability

3105 aluminum alloy not only meets modern environmental standards but also boasts good recyclability, in line with sustainable development principles. The high recyclability of aluminum reduces resource consumption during production and helps reduce the environmental burden. Furthermore, the DOS coating also complies with environmental requirements, ensuring that no harmful substances are generated during production, making 3105 aluminum alloy an attractive option in packaging industries with strict environmental regulations.

Strong Adaptability

3105 aluminum alloy can meet diverse design requirements, offering highly customized services. Its excellent processability and adaptability make it suitable for producing pilfer-proof bottle caps of various sizes, shapes, and functions. It is widely used in industries such as food, pharmaceuticals, and cosmetics, meeting the specific needs of different sectors.

Cost-Effectiveness

Compared to other aluminum alloys, 3105 aluminum alloy has a lower production cost, making it more cost-effective for mass production. Its good processing performance further improves production efficiency, reducing production costs. For large-scale production of pilfer-proof bottle caps, 3105 aluminum alloy provides an economical solution while maintaining high quality and performance.