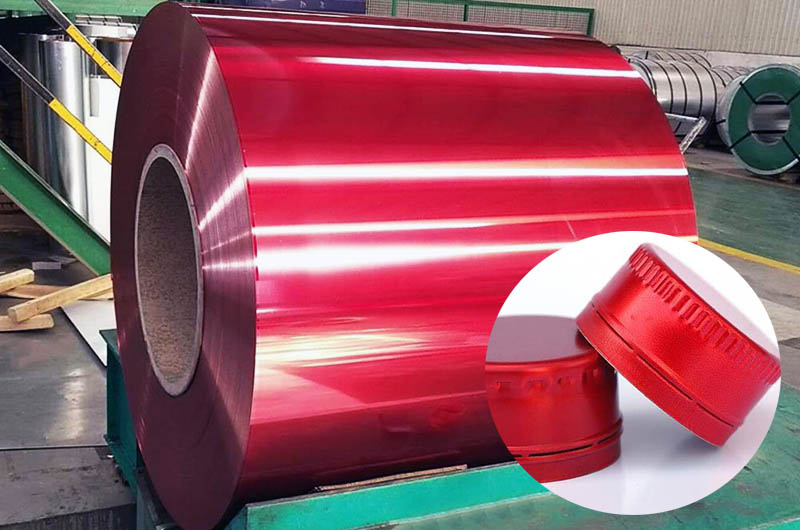

Both Side Clear Lacquer Aluminum Coil Sheet for ROPP Caps

Last Updated :Mar. 07, 2024

Learn about ROPP caps

ROPP bottle caps are widely preferred for their anti-theft and leak-proof sealing capabilities. They are commonly used to seal glass and plastic bottles containing beverages, pharmaceuticals and cosmetics. ROPP bottle cap designs typically include an aluminum shell with a plastic or cork lining to ensure a secure closure.

Introduction to double-sided varnish technology

Double-sided varnish Unlike the traditional method of painting only one side of the aluminum coil, double-sided varnish technology allows both sides to be painted at the same time. This increases transparency, thereby increasing visibility of the underlying aluminum substrate, while retaining the protective properties of the paint.

The traditional manufacturing process for ROPP bottle caps involves using plain aluminum coils, which are subsequently painted on one side. While this approach is effective in ensuring seal integrity, it has limitations in terms of aesthetics and visibility of brand elements.

Aluminum Coil Sheet for ROPP Caps The purpose of varnishing

Applying varnish can effectively isolate the contact between air and water and prevent oxidation and corrosion on the surface of aluminum coil plates.

Varnish can also enhance the gloss and brightness of aluminum coils and sheets, making them more attractive and high-end in appearance.

- 1. Applying varnish increases the corrosion resistance of the aluminum plate. An oxide film is easily formed on the surface of the aluminum plate, which can protect the aluminum plate from corrosion. However, if the surface of the aluminum plate is damaged or scratched, these areas are prone to corrosion. Applying varnish can effectively isolate the contact between air and water and prevent oxidation and corrosion on the surface of the aluminum plate.

- 2. The clear paint coating improves the aging resistance of the aluminum plate. Aluminum plates are easily oxidized in the air, causing aging phenomena such as yellow spots on the surface. Applying varnish can effectively slow down the oxidation process of aluminum plates and extend their service life.

- 3. The varnish coating increases the barrier properties of the aluminum plate. The varnish can form a dense film on the surface of the aluminum plate, effectively blocking the entry of air and water, and preventing the penetration and leakage of liquid substances such as food and beverages.

- 4. The clear paint coating enhances the processing performance of the aluminum plate. During the processing of aluminum plates, processes such as stamping and forming are required, which may cause scratches and damage to the surface of the aluminum plates. Using a double-sided varnish can mask these issues and improve the quality and appearance consistency of your caps.

The clear-coated aluminum coils and plates used for ROPP bottle caps are coated with varnish coating on both sides, which not only enhances the aesthetics and corrosion resistance of the aluminum plate, but also increases its corrosion resistance, aging resistance, barrier performance and processing performance. Double-sided varnished aluminum coils for ROPP bottle caps are widely used in the aluminum bottle cap manufacturing industry and can be used to produce various types of aluminum bottle caps, such as food-grade bottle caps and health product bottle caps.

Double-sided varnished aluminum coil plate for ROPP bottle caps is a material used to make double-sided varnished aluminum caps. It is usually made of aluminum alloy material and requires surface oxidation treatment to improve its hardness and wear resistance.

Both Side Clear Lacquer Aluminum Coil Sheet for ROPP Caps Features and Benefits

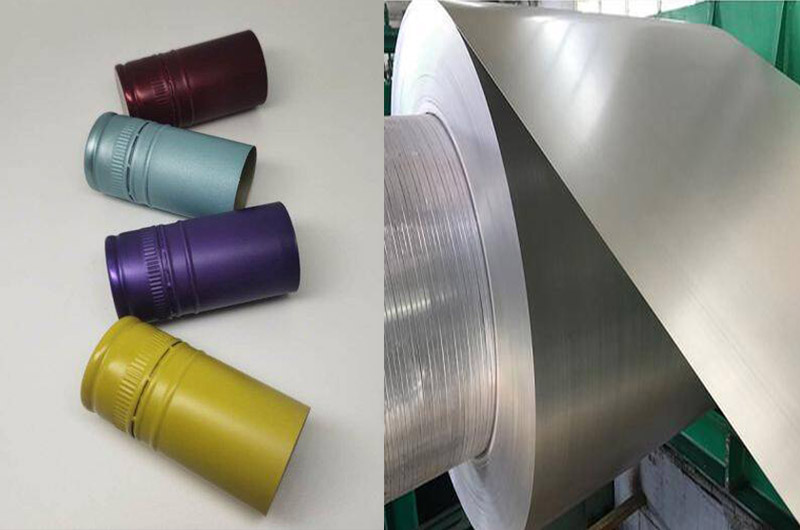

- 1. Enhance aesthetics: Double-sided varnished aluminum coil plate has excellent transparency, allowing the aluminum substrate below to be clearly seen. This transparency enhances the visual appeal of ROPP caps, allowing brand logos, designs and colors to stand out.

- 2. Brand differentiation: With double-sided varnish technology, brands have the opportunity to differentiate their products through unique design and brand elements. Clearcoat coatings act as a canvas for creative artwork and branding, allowing manufacturers to effectively communicate their brand image to consumers.

- 3. Improve product visibility: Transparency plays a vital role in product visibility, especially in industries such as beverages and cosmetics, where beautiful packaging affects consumers' purchasing decisions. Double-sided varnished aluminum coil ensures the contents of the bottle are clearly visible, enhancing product display on retail shelves.

- 4. Seal integrity: Despite the emphasis on aesthetics, double-sided varnish technology does not affect seal integrity. The varnish coating on both sides of the aluminum substrate can effectively prevent the influence of moisture, oxygen and other environmental factors, ensuring the integrity of the sealed product.

- 5. Sustainability: Aluminum is inherently recyclable, making it an environmentally friendly choice for packaging applications. Double-sided varnished aluminum coils contribute to sustainability by facilitating the recycling of ROPP bottle caps without compromising performance or aesthetics.

When selecting aluminum coils and aluminum plates for ROPP bottle cap materials, factors such as their compatibility with the aluminum bottle body, sealing performance, and corrosion resistance need to be considered. In addition, additives can be added to the double-sided or single-sided varnished aluminum coil plate for bottle caps to enhance its anti-aging, antibacterial and other special properties, while meeting the requirements for bottle cap sealing and food safety.

Both Side Clear Lacquer Aluminum Coil Sheet for ROPP Caps Applications

Double-sided varnished aluminum coil sheets are suitable for various industries that use ROPP covers for packaging.

- 1. Beverage industry: Double-sided varnish ROPP caps are widely used to seal bottles of water, soft drinks, juices and alcoholic beverages. Enhanced transparency and branding opportunities make them ideal for premium beverage brands looking to differentiate their products on shelf.

- 2. Pharmaceutical industry: Pharmaceutical companies rely on safe packaging solutions to ensure the integrity and safety of their products. Double-sided varnished ROPP caps provide a tamper-evident seal, protecting pharmaceutical formulations from contamination and adulteration.

- 3. Cosmetics industry: The cosmetics industry emphasizes beautiful packaging to attract consumers and convey brand value. Double-sided varnished ROPP caps enhance the visual appeal of cosmetic products, allowing consumers to see the contents while reinforcing the brand image through innovative design.

The introduction of double-sided varnish technology provides manufacturers with a versatile solution that combines functionality with aesthetics. By increasing the transparency and branding opportunities of ROPP closures, the technology enables brands to create unique packaging experiences that resonate with consumers.