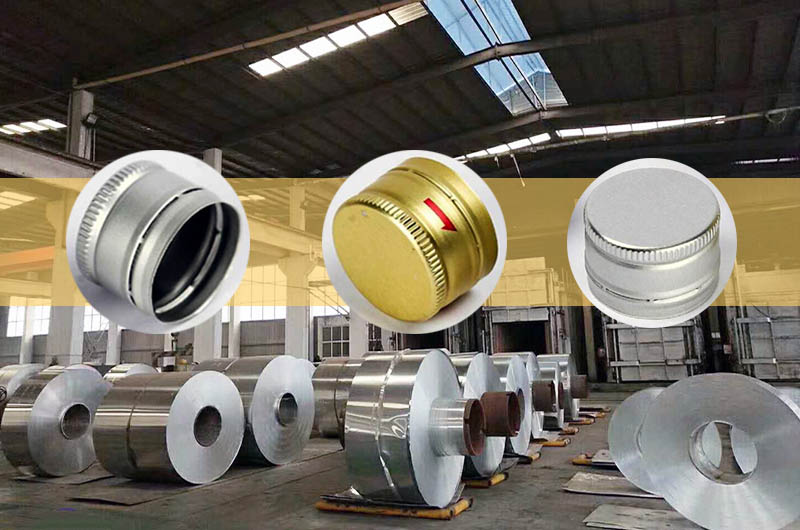

Clear Lacquer Aluminum Coil and Sheet for Pilfer Proof Caps

Last Updated :Mar. 13, 2024

Aluminum is a versatile material that is widely used in various industries due to its unique properties such as being lightweight, corrosion-resistant and recyclable. One of the important applications of aluminum is in packaging, especially in the production of anti-theft caps for bottles and containers. Clear-coated aluminum coils and sheets play a key role in the manufacture of these covers, ensuring functionality and aesthetics.

Anti-theft covers are made of varnished aluminum coils and sheets. The coating of varnish can protect the surface of the aluminum plate from damage during processing and use. In addition to 3105 PP painted aluminum coils and sheets for caps, there are other aluminum alloy materials that can be used to make bottle caps, such as 8011 alloy. These materials have different mechanical properties and corrosion resistance and can be selected according to actual needs.

Varnished aluminum coil and sheet for anti-theft caps is a type of aluminum sheet used to make bottle caps. This aluminum is widely used in the manufacture of various bottle caps because it is lightweight, beautiful, durable and easy to process. Aluminum coils and sheets for PP bottle caps are usually made of aluminum alloy and have excellent mechanical properties and corrosion resistance. At the same time, the painted aluminum coils and plates used for bottle caps also have good plasticity and ductility, and can be processed into bottle caps of various shapes and sizes.

Learn about Pilfer Proof Caps

Anti-theft lids, also known as tamper-evident lids or tamper-evident lids, are designed to provide security and integrity to packaged goods by preventing unauthorized access or tampering. These lids have a unique sealing mechanism that makes it difficult for unauthorized individuals to open the container without leaving obvious signs of tampering. Anti-theft caps are commonly used in the pharmaceutical, food and beverage, and chemical industries to protect the contents of bottles and containers, ensuring product safety and consumer trust.

Introduction to Clear Lacquer Aluminum Coil and Sheet

Varnished aluminum coils and aluminum plates are the main materials for manufacturing anti-theft covers. These coils and sheets undergo a specialized coating process that creates a clear lacquer layer that enhances the visual appeal of the aluminum surface while providing protection against corrosion and chemical reactions. The varnish coating not only ensures the longevity of the bottle cap, but also enables seamless printing of logos, text and other designs, further increasing brand awareness and recognition.

Reasons for using Clear Lacquer Aluminum Coil and Sheet for Pilfer Proof Caps

1. Protective cap material

The varnish protects the anti-theft cover aluminum sheet from external environmental factors (such as ultraviolet rays, humidity) and prevents it from aging, discoloration or deterioration.

2. Increase aesthetics

A clear varnish coating can make the bottle cap look more beautiful and bright, enhancing the overall texture of the product.

3. Anti-slip effect

The transparent varnish can form a smooth coating on the surface of the bottle cap, which plays an anti-slip role and makes it easier for users to open the bottle cap.

4. Prevent liquid leakage

For some bottles containing liquids, varnish can prevent liquid leakage and improve the sealing performance of the product.

5. Extend service life

The varnish protects the aluminum coils and sheets used in anti-theft covers from microbial attack, thus extending the service life of the product.

6. Increase adhesion

Applying varnish to the aluminum sheet for pp cover can increase its adhesion and make it easier to stick to other objects.

7. Prevent oxidation

The varnish can prevent the PP cover aluminum coil from being oxidized when exposed to the air.

Clear Lacquer Aluminum Coil and Sheet for Pilfer Proof CapsPerformance Features

Clear-coated aluminum coils and sheets offer a variety of properties and performance characteristics that make them ideal for tamper-evident cover applications. These properties include:

- 1. Transparency: A clear varnish coating imparts transparency to the aluminum surface, allowing excellent visibility of printed designs, text and product content. This transparency enhances the cap’s aesthetics and promotes brand recognition.

- 2. Corrosion resistance: The aluminum base plate, combined with a protective paint coating, exhibits excellent corrosion resistance, ensuring long-term durability and protecting against the effects of environmental factors such as moisture, humidity and chemical exposure.

- 3. Adhesion: The clear varnish coating has strong adhesion to the aluminum substrate, preventing delamination or peeling even under harsh conditions such as mechanical stress or temperature fluctuations.

- 4. Flexibility: The varnish coating provides flexibility and consistency, allowing the aluminum to be easily shaped into a variety of bottle cap designs without cracking or breaking.

- 5. Chemical resistance: Clear-coated aluminum coils and sheets are resistant to a wide range of chemicals commonly found in packaging applications, including acids, alkalis and organic solvents, ensuring the integrity of the lid and its contents.

- 6. Printability: The clear varnish coating provides a smooth and uniform surface for high-quality printing of logos, brand elements, barcodes and other graphics using various printing technologies such as offset, flexographic or digital printing.

- 7. Heat Resistance: The clear varnish coating is heat resistant, allowing the cap to withstand sterilization processes such as autoclaving or pasteurization without affecting integrity or appearance.

- 8. Recyclability: Aluminum and clearcoat coatings are both fully recyclable materials, contributing to sustainability and environmental responsibility in packaging applications.

Together, these properties contribute to the superior performance and functionality of varnished aluminum coils and sheets in the manufacture of anti-theft lids, meeting the stringent requirements of the packaging industry and ensuring consumer safety and satisfaction.

Applications of Pilfer Proof Caps

Varnished aluminum coils and sheets are widely used in the production of anti-theft covers for various packaging applications in different industries. Some key applications include:

- 1. Beverage packaging: Varnished aluminum caps are widely used for bottling beverages such as carbonated drinks, juices, water and alcoholic beverages to provide tamper-proof sealing and product freshness.

- 2. Pharmaceutical packaging: Pharmaceuticals require secure and tamper-proof packaging to ensure product safety and regulatory compliance. Varnished aluminum lids are used in the packaging of medicines, syrups and other pharmaceutical preparations to protect the integrity of the contents.

- 3. Food packaging: In the food industry, varnished aluminum lids are used to seal containers of condiments, sauces, cooking oils and other foods to prevent contamination and maintain freshness.

- 4. Cosmetics and personal care product packaging: Varnished aluminum lids bring high-quality aesthetics to cosmetics and personal care products such as perfumes, lotions and skin care formulas, enhancing brand image and consumer awareness.

- 5. Chemical and Industrial Packaging: Chemicals, solvents, and industrial fluids require secure packaging to prevent leaks, spills, and tampering. Such products are packaged with clear-coated aluminum lids to ensure safety and integrity throughout storage and transportation.

- 6. Wine and Spirits Packaging: Premium wine and spirits brands use varnished aluminum caps to seal bottles, preserving the quality and flavor of alcoholic beverages while enhancing shelf appeal and brand recognition.

- 7. Automotive and lubricant packaging: Varnished aluminum caps are also used for packaging automotive fluids, lubricants and specialty chemicals, providing a secure seal and preventing contamination and deterioration.

Manufacturing Process of Clear Lacquer Aluminum Coil and Sheet

The manufacturing process of varnished aluminum coils and sheets involves multiple consecutive steps, each of which is critical to ensuring the quality and performance of the final product. The process can be roughly divided into the following stages:

- 1. Aluminum coil preparation: Raw aluminum coils undergo a series of mechanical and chemical treatments to remove impurities, enhance surface cleanliness, and improve adhesion. This may include degreasing, caustic washing, rinsing and chemical conversion coatings to promote bonding between the aluminum substrate and the paint coating.

- 2. Application of primer: Apply a layer of primer to the cleaned and treated aluminum surface to improve adhesion and corrosion resistance. Primer formulations may contain special additives to enhance compatibility with subsequent clearcoat coats and improve the overall performance of the system.

- 3. Application of varnish coating: The varnish coating is applied to the primed aluminum surface using various coating methods (such as roller coating, spray coating or coil coating). Coating thickness is carefully controlled to achieve the desired clarity and protection while maintaining uniformity across the entire surface.

- 4. Curing and drying: After painting, the coated aluminum coil or sheet undergoes a curing process to promote cross-linking and polymerization of the resin system. This step is critical to achieve the desired film properties such as hardness, adhesion, and chemical resistance. Depending on the formulation, curing can be by thermal or UV radiation methods.

- 5. Inspection and quality control: After curing, varnished aluminum coils and plates undergo strict inspection and quality control measures to ensure compliance with specified requirements.

The versatility, durability and aesthetics of varnished aluminum coil and sheet make it an integral part of modern packaging solutions, serving the needs of a wide range of consumer and industrial applications.

Clear-coated aluminum coils and sheets play a key role in the production of tamper-evident covers, providing the transparency, durability and functionality necessary for modern packaging applications.