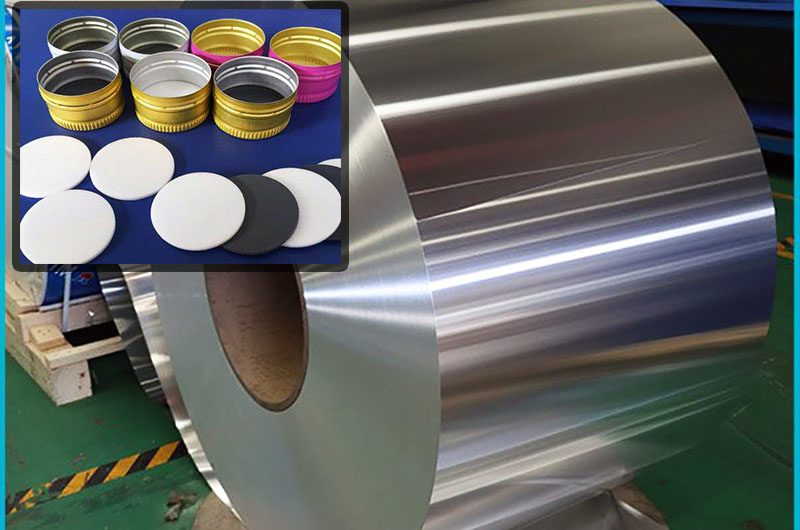

Aluminum for Closure PP Caps CC 3105

Last Updated :Apr. 09, 2024

Aluminum alloy CC 3105 is another common material used in the production of PP (polypropylene) closures and offers similar advantages to DC 3105 alloy.

CC stands for continuous casting, which is an aluminum production process. CC 3105 product is suitable for the production of bottle caps for various products, such as wine bottle caps, cosmetic PP caps, pharmaceutical bottle caps, beverage caps, etc.

Through processes such as continuous annealing, tension leveling, conversion and electrostatic protection, excellent elongation and adhesion properties are ensured, as well as perfect conditions for painting and drawing. In addition, Haomei Aluminum also uses a variety of processes to achieve the results expected by customers, such as the DOS re-oiling process, which can handle the board without scratching and achieve optimal paint adhesion.

Why is CC 3105 aluminum alloy suitable for making closed PP covers?

- 1. Corrosion resistance: Like DC 3105, CC 3105 aluminum alloy has excellent corrosion resistance, ensuring the integrity of the closure even when exposed to moisture, acids, or other corrosive substances commonly found in packaging environments. This tolerance is critical to maintaining product quality and safety, especially for food and beverage packaging applications.

- 2. Formability: CC 3105 aluminum alloy is highly formable, allowing manufacturers to shape it into the precise sizes and configurations required for PP closures. This formability facilitates the production of caps with intricate designs, custom embossing, or unique features tailored to specific packaging needs.

- 3. Sealing performance: The PP closing cap made of CC 3105 aluminum alloy provides a reliable seal for the container, ensuring freshness and preventing leakage or contamination. The combination of aluminum's malleability and polypropylene's flexibility allows the lid to form a strong seal over the container opening, effectively maintaining product quality during storage and transportation.

- 4. Light weight: Aluminum is inherently lightweight and has the advantage of reducing the overall weight of the packaging material. Sealing lids made from CC 3105 alloy help enable lightweight packaging solutions that save on shipping and handling costs while improving consumer convenience.

- 5. Recyclability: Sustainability is an important consideration in packaging design, and CC 3105 aluminum alloy supports environmentally friendly practices. Aluminum is fully recyclable without losing its properties, making it ideal for closed-loop recycling systems. By using sealing caps made from recyclable aluminum alloy, manufacturers can contribute to reducing waste and conserving natural resources.

- 6. Secure closure: CC 3105 aluminum alloy closure caps provide a secure closure mechanism for containers, ensuring product integrity and preventing spillage or tampering. The durability of aluminum and the flexibility of polypropylene combine to create a tight seal that remains intact throughout the product's shelf life.

- 7. Versatility: Sealing lids made of CC 3105 aluminum alloy can be customized to meet specific packaging requirements such as branding, anti-tamper features or enhanced functionality. Aluminum’s versatility can be incorporated into innovative design elements that enhance the user experience and make products stand out in the market.

Aluminum alloy CC 3105 is a material suitable for closing PP caps due to its corrosion resistance, formability, sealing properties, lightweight properties, recyclability, secure closure and versatility.

The Specification of Aluminum for Closure PP Caps CC 3105

| Alloy | 3105 Aluminum Alloy |

| Temper | H14, H16, H24, H26, H44, H46 |

| Thickness | 0.15-0.45mm |

| Type | Sheet/Coils/Foils/Strips |

| Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

| Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

Mechanical Property of Aluminum For Closure PP Caps CC Material 3105

| Alloy | 3105 |

| Temper | H14 |

| Thickness (mm) | 0.16~0.23 |

| U.T.S (Mpa) | 185~205 |

| Elongation (%) | R2 |

The Advantages of Aluminium for PP Caps CC 3105

- 1. Stable mechanical properties: The mechanical properties of this aluminum material are stable, the manufacturing process is good, and the stability of the parts or the occurrence of stumbling is less than 2%. This means that during the production process, the properties of the aluminum material can be reliably controlled and the occurrence of ears is very low.

- 2. Good plasticity: PP cover CC3105 aluminum has good plasticity and can be deep drawn. The maximum drawing depth can reach 75mm, and there will be no "orange peel" phenomenon after stamping. This shows that the aluminum material is suitable for applications that require deep machining and that the surface quality remains good after machining.

- 3. Better surface quality: The surface quality of this aluminum material is better, with uniform fine lines, which means it has a more beautiful appearance, high surface smoothness, and no obvious flaws.

- 4. High thickness accuracy: The thickness accuracy of PP cover CC3105 aluminum can reach +0.005mm, which means that during the processing process, the thickness of the aluminum material can be accurately controlled, ensuring the dimensional accuracy of the product and improving the reliability and reliability of manufacturing. stability.