Aluminum for Closure PP Caps DC 3105

Last Updated :Apr. 10, 2024

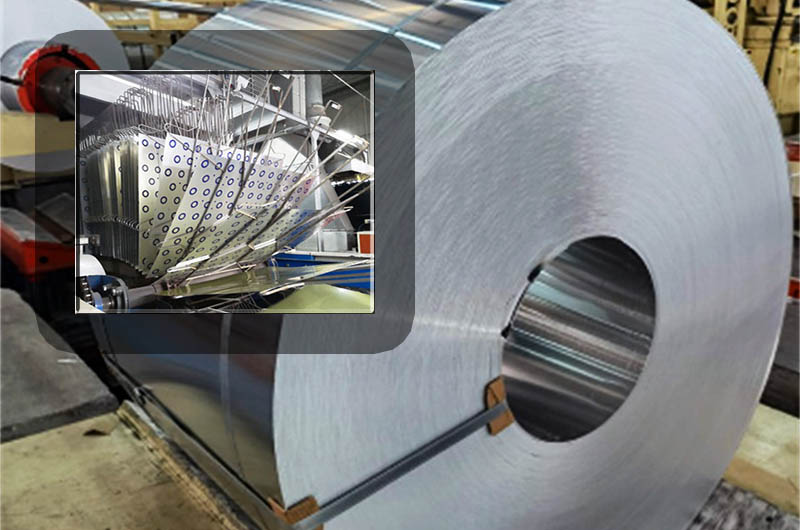

Aluminum alloy 3105 is commonly used in the production of PP (polypropylene) bottle caps. 3105 aluminum alloy has excellent corrosion resistance and formability, making it suitable for applications where exposure to moisture or other corrosive elements is expected. Closing PP lids made from aluminum alloy 3105 provide reliable sealing for various containers such as bottles and jars, ensuring product integrity and freshness. Additionally, aluminum closures are lightweight, recyclable, and provide a secure closure, making them the first choice in the packaging industry.

Aluminum alloy 3105 is a popular choice for PP closures due to its excellent properties and suitability for packaging applications.

Aluminum DC 3105 for PP caps has good anti-rust properties and good deep drawing effect. Since aluminum bottle caps are mostly processed on production lines with high automation requirements, the requirements for the strength, elongation and processing performance of aluminum 3105 for bottle caps are very high, and 3105 aluminum for bottle caps has excellent characteristics and various The performance meets the production requirements of bottle caps, and there are no creases or cracks during processing.

Closure PP Caps Why Choose DC 3105 Aluminum Sheet Coil?

- 1. Corrosion resistance: 3105 aluminum alloy has excellent corrosion resistance, which is a key factor for packaging materials, especially packaging materials for food and beverage products. This resistance ensures that PP closures maintain their integrity even when exposed to a variety of substances, including liquids, acids and other corrosive elements commonly found in packaging environments.

- 2. Formability: One of the main advantages of 3105 aluminum alloy is its excellent formability. This property allows manufacturers to efficiently shape the material into the complex designs and sizes required for PP closures. Whether the cap needs to be embossed, stamped or formed into a specific shape, this alloy provides the versatility needed to meet different packaging requirements.

- 3. Sealing performance: The closed PP cap made of aluminum alloy 3105 provides reliable sealing for containers such as bottles and jars. The malleability of aluminum and the inherent flexibility of polypropylene combine to ensure a tight fit to the container opening, effectively maintaining the freshness of the contents and preventing leakage or contamination.

- 4. Lightweight: Aluminum is inherently lightweight, making it ideal for closure caps. This feature reduces the overall weight of the package, helping to save on shipping and handling costs. In addition, lightweight caps are easier for consumers to open and close, thereby enhancing the user experience.

- 5. Recyclability: Sustainability is a growing concern in the packaging industry, and aluminum closures offer an environmentally friendly solution. Aluminum is fully recyclable, and the recycling process consumes far less energy than producing new aluminum from raw materials. By choosing sealing covers made of aluminum alloy 3105, manufacturers can contribute to the circular economy and reduce their impact on the environment.

- 6. Secure closure: The durability of aluminum and the flexibility of polypropylene combine to ensure a secure closure of the container. This feature is critical to maintaining product freshness, preventing spills or leaks during shipping, and maintaining the overall quality of packaged goods.

- 7. Versatility: Aluminum closures can be customized to meet specific packaging requirements, such as branding, tamper-evident features, or special features such as pour spouts or dispensing mechanisms. The versatility of aluminum alloy 3105 allows manufacturers to innovate and create unique packaging solutions that suit their products and target markets.

Aluminum alloy 3105 is an excellent choice for closed PP caps due to its corrosion resistance, formability, sealing properties, lightweight, recyclability, secure closure and versatility.

The Specification of Aluminum for Closure PP Caps DC 3105

| Alloy | 8011/3105 Aluminum Alloy |

| Temper | H14, H16, H24, H26, H44, H46 |

| Thickness | 0.15-0.45mm |

| Type | Sheet/Coils/Foils/Strips |

| Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

| Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

Mechanical Property of Aluminum for Closure PP Caps DC Material 3105

| Alloy | 3105 |

| Temper | H14 |

| Thickness (mm) | 0.16~0.23 |

| U.T.S (Mpa) | 125~155 |

| Elongation (%) | R2 |

Advantages of PP cover DC 3105 aluminum

- 1. The chemical composition, rolling reduction and temperature can be adjusted to obtain higher material strength, thereby reducing the thickness of the sheet (making it lighter).

- 2. Haomei Aluminum controls the material composition, rolling temperature and time, and annealing temperature to produce the best material to meet customers' performance requirements such as opening capacity and ear making.

- 3. If necessary, we can treat the aluminum of the cap material with phosphate chromate or zirconium to improve paint adhesion.

- 4. We carefully monitor the flatness and squareness of the aluminum sealing plate to prevent color aberration, unevenness or printing misalignment during the printing process.