Color Coated Aluminium Strip: The Perfect Choice for Wine & Medicine Caps

Last Updated :Feb. 08, 2025

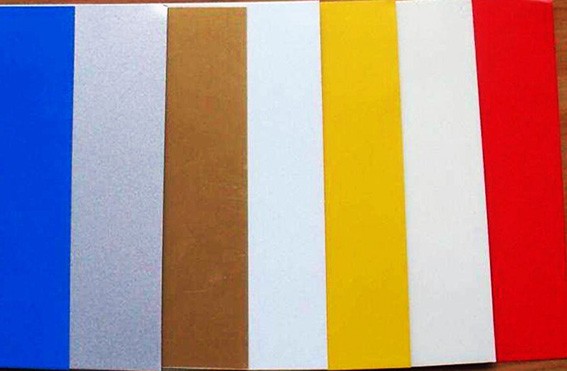

Color-coated aluminum strip is a high-quality material widely used for manufacturing wine and pharmaceutical bottle caps. This material features excellent surface treatment, vibrant color options, and multiple alloy choices, ensuring durability, safety, and aesthetics. It plays a crucial role in the production of bottle caps across various industries, including alcoholic beverages, pharmaceuticals, and cosmetics.

Color-coated Aluminum Cap Strip Surface Treatment and Coating Types

The color-coated aluminum strip undergoes advanced surface treatments to enhance its functionality and appearance. Common processing methods include:

- Glossy surface treatment: Provides a smooth and reflective surface.

- Coating treatment: Includes PE (polyester) coating and epoxy resin coating to improve durability and corrosion resistance.

- Printing: Can be customized with brand logos, patterns, or specific color designs.

These coatings not only enhance aesthetic value but also improve aluminum’s resistance to oxidation, moisture, and external contaminants, ensuring long-term performance.

Color-coated Aluminum Cap Strip Specification

| Alloy | 1060, 3003, 3105, 5052, 8011 |

| Temper | H18, H19, H22, H24, H26,H14,H16 |

| Thickness | 0.15-0.5mm |

| Width | 500~2500mm |

| Rolling technique | CC/DC |

| Surface treatment | Color coated |

| Application | Red wine caps, anti-theft bottle caps, perfume bottle caps, skin care bottle caps, cosmetic bottle caps, oil caps, oral liquid aluminum-plastic composite caps, infusion bottle aluminum-plastic caps, etc. |

| Delivery date | 15-21 days |

| Packaging | Wooden pallet |

| Samples | Free of charge |

Customization Options

Haomei Aluminum can customize color-coated aluminum strips according to specific requirements, offering:

- A variety of colors and patterns to meet branding needs.

- Customized thickness and width for different types of bottle caps.

- Special coatings to enhance the durability and resistance of bottle caps to environmental factors.

Color-coated Aluminum Cap Strip Alloy Options and Their Characteristics

The most commonly used alloys for color-coated aluminum strips include:

- 1060: High-purity aluminum with excellent corrosion resistance and flexibility.

- 3003: Manganese-based alloy with enhanced strength and rust resistance.

- 3105: Higher corrosion resistance and strength compared to 3003.

- 5052: Magnesium-aluminum alloy known for its excellent strength and corrosion resistance.

- 8011: Widely used for bottle caps due to its excellent sealing performance and formability.

These alloys ensure that bottle caps are durable, lightweight, and easy to manufacture, meeting the needs of various industries.

Color-coated Aluminum Cap Strip Applications in Bottle Caps

Color-coated aluminum strip is an essential material for various bottle cap applications, including:

- Wine and beverage bottle caps: Used for PP caps, ROPP caps, and screw caps, suitable for beer, wine, spirits, and soft drinks.

- Pharmaceutical bottle caps: Ensuring the sealing and tamper-proof protection of medicine bottles.

- Cosmetic bottle caps: Used for perfume bottles, skincare products, and other beauty industry packaging.

- Anti-counterfeit bottle caps: Providing security features to prevent tampering and ensure product authenticity.

One of the most notable advantages of using color-coated aluminum strips is that they are free from Bisphenol A (BPA), making them a safe and non-toxic choice for bottle caps. They comply with international food safety standards, ensuring consumer health. Additionally, aluminum is 100% recyclable, contributing to environmental sustainability.

Due to its superior performance, safety, and customization options, color-coated aluminum strip is the ideal choice for wine and pharmaceutical bottle caps. Whether used in beverage packaging, pharmaceutical sealing, or premium cosmetics, this material ensures high performance, aesthetics, and consumer safety, making it the preferred solution for manufacturers worldwide.