Mill Finish 8011 h14 Aluminum Foil for Bottle Cap

Last Updated :Apr. 10, 2024

Aluminum foil has become an indispensable material in various industries due to its versatility, lightness and excellent barrier properties. Among its many applications, aluminum foil for bottle cap sealing stands out as a key component of the packaging industry, ensuring product integrity, freshness and safety. There have been significant developments in finishing aluminum foil in recent years, particularly 8011 H14 alloy, which has received significant attention in bottle cap sealing applications.

Understanding Mill Finish Aluminum Foil

Mill Finish Aluminum Foil refers to aluminum foil that has been rolled through a rolling process without any additional surface treatment or finishing. It retains a natural, unpolished look and features a matte finish. This original form of aluminum foil offers several advantages, including cost-effectiveness, ease of manufacturing and enhanced ductility. Mill Finish Aluminum Foil can be used as a base material for a variety of surface treatments and coatings, making it a versatile choice for different applications.

The significance of 8011 H14 aluminum alloy

8011 H14 alloy is a popular choice for aluminum foil production, particularly in bottle cap sealing applications. The alloy belongs to the 8xxx series of aluminum alloys, known for its excellent formability, corrosion resistance and suitability for cold working processes. The designation "H14" refers to the tempered state of the alloy, indicating that it has been strain hardened and partially annealed to obtain specific mechanical properties. When it comes to bottle cap sealing, 8011 H14 alloy offers optimal strength and flexibility, ensuring reliable performance in sealing applications.

Characteristics of 8011 H14 Mill Finish Aluminum Foil

- 1. Thickness: The thickness of mill finish aluminum foil used for capping is usually 0.015 mm to 0.5 mm, which varies according to specific requirements and application needs.

- 2. Strength and durability: 8011 H14 alloy has high tensile strength and durability, allowing it to withstand the rigors of the bottle cap sealing process without compromising performance.

- 3. Flexibility: Finished aluminum foil retains excellent flexibility and can be seamlessly applied to various types and shapes of containers, ensuring a tight seal and preventing leaks.

- 4. Barrier performance: Aluminum foil can effectively block moisture, light, oxygen and other environmental factors, maintaining the freshness and quality of packaged products.

- 5. Compatibility: 8011 H14 alloy is compatible with a variety of sealing methods, including induction sealing, heat sealing and pressure sensitive sealing, providing versatility in packaging solutions.

Mill Finish Aluminum Foil Manufacturing Process

The production of finished aluminum foil involves multiple stages, starting with the casting of aluminum ingots. These ingots are then hot rolled into thin sheets and then cold rolled to achieve the required thickness and mechanical properties. 8011 H14 alloy undergoes an annealing and tempering process to enhance its strength and formability while maintaining optimal ductility. The final step is to slit and cut the foil to the required size to meet the customer's specifications. Quality control measures are implemented throughout the manufacturing process to ensure consistency and adherence to strict standards.

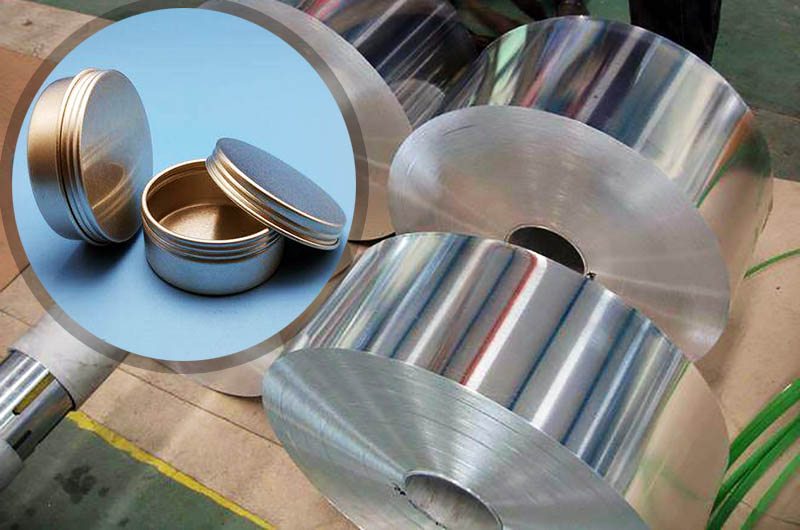

Applications of Mill Finish Aluminum Foil in bottle cap sealing

8011 aluminum foil is often used to make aluminum covers. Its performance is better than pure aluminum foil and it is widely used in aluminum foil. 8011 aluminum foil is one of the commonly used aluminum bottle cap materials. The status is H14/H16, the thickness range is 0.15~0.27mm, and the width range is 330~1000mm. It can be used to produce wine caps, easy-open caps, medicine bottle caps, and milk powder caps. Tear off cover etc.

Mill Finish Aluminum Foil for Beverage Bottle Cap: Finished aluminum foil is widely used in the beverage industry to seal bottles and containers containing carbonated drinks, juices, water and other beverages. The foil effectively preserves the beverage's carbonation and flavor while preventing contamination and spoilage.

Mill Finish Aluminum Foil for Pharmaceutical Bottle Cap: In the pharmaceutical industry, mill Finish Aluminum Foil is used to seal pharmaceutical bottles, vials and blister packs to ensure product integrity, tamper resistance and compliance with regulatory standards.

Mill Finish Aluminum Foil for food packaging: Finished aluminum foil is widely used in food packaging applications, including sealing cans, jars and bags containing sauces, condiments, dairy products and ready-to-eat meals. Foil effectively blocks external contaminants and extends the shelf life of packaged foods.

Advantages of finished aluminum foil for bottle cap sealing

Finished aluminum foil for bottle caps 8011 h14 can be used to make bottle caps. 8011 aluminum foil is an aluminum foil series, which belongs to the alloy aluminum foil series. Al-Fe-Si elements are added, and its alloy properties account for more than 1% of the total alloy elements, which has high advantages.

- 1. Enhanced barrier properties: Finished aluminum foil has superior barrier properties compared to alternative packaging materials, protecting packaged products from moisture, oxygen and light.

- 2. Customization options: Manufacturers can customize finished aluminum foil to specific requirements, including thickness, width and surface treatment, to meet different packaging needs and brand preferences.

- 3. Environmental sustainability: Aluminum foil is recyclable and can be easily recycled and reused, contributing to environmental sustainability and reducing the carbon footprint of the packaging industry.

- 4. Cost-Effectiveness: Finished aluminum foil represents a cost-effective packaging solution that delivers high performance at a competitive price, thus improving the overall operational efficiency and profitability of a business.

Finished aluminum foil for bottle caps 8011 h14 can also be used in the manufacture of bottle caps, especially in applications where high gloss and aesthetics are required. The surface of the precision-machined aluminum plate is smooth and the appearance is bright, making the produced bottle caps have better visual effects and texture. In addition, the precision-machined aluminum plate has good corrosion resistance, plasticity and processing properties, and can meet the requirements of bottle cap production.