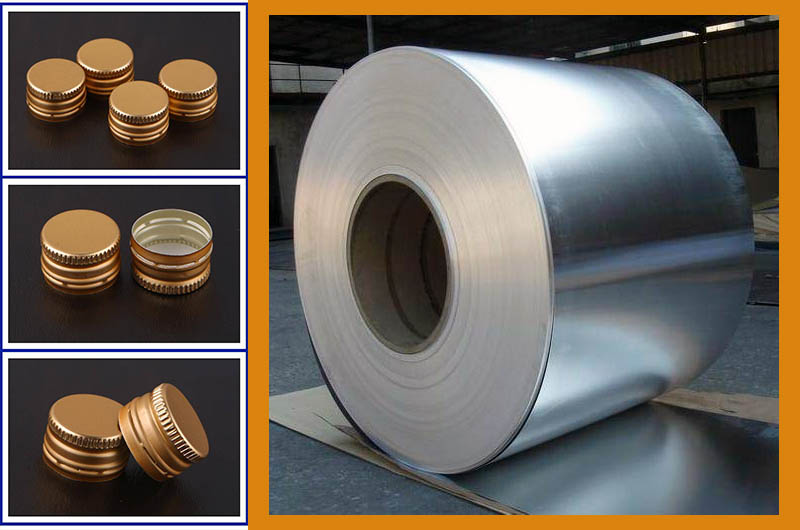

ROPP Cap Closure Printed Aluminum Sheet

Last Updated :May. 15, 2024

Among the ever-changing packaging solutions, ROPP (roller ball anti-theft) capping systems have become an important choice for sealing various containers. The use of printed aluminum plates complements this robust sealing mechanism, which not only increases brand recognition but also provides functional benefits.

ROPP capping printed aluminum plate has undergone special surface treatment and is a high-quality aluminum and aluminum alloy substrate. It has excellent flatness, corrosion resistance and decorative properties, so it is widely used in the packaging field.

ROPP bottle caps stand out for their reliability and tamper-proof features. Meanwhile, printed aluminum panels are gaining attention for their versatility and aesthetics. The fusion of these two technologies resulted in ROPP capped printed aluminum panels, providing a seamless blend of functionality and branding opportunities.

The ROPP cap closure system consists of an aluminum cap with threads rolled onto the bottle neck, providing a secure seal that prevents tampering and theft. This mechanism ensures product integrity and consumer confidence, making it the first choice for a variety of applications including pharmaceuticals, beverages and cosmetics.

Printed aluminum sheet for closure ROPP Cap structure

The printed aluminum sheets used in ROPP bottle caps are typically composed of multiple layers for optimal performance.

- The base layer is made of high-quality aluminum alloy, providing structural strength and corrosion resistance.

- On top of the base layer, a primer coat is applied to promote adhesion of the printed design.

- The top layer consists of specialized inks or coatings that enable vibrant printing while ensuring durability and resistance to external factors such as UV radiation and moisture.

Advantages of printed aluminum plate for closure Ropp Cap

Printing aluminum sheets with ROPP capping offers multiple advantages to manufacturers and consumers.

- 1. The tamper-proof properties of ROPP caps ensure the safety and integrity of the product and reduce the risk of contamination or adulteration. This capability is particularly important in industries such as pharmaceuticals and food where consumer health is critical.

- 2. The versatility of printed aluminum allows complex designs, vibrant colors and branding elements to be seamlessly incorporated into packaging. This not only enhances shelf appeal but also drives brand recognition and consumer engagement.

- 3.ROPP lid closed printed aluminum plate has excellent barrier properties, protecting the contents from external factors such as light, oxygen and moisture. This helps extend the shelf life of perishable products and maintain product quality throughout the distribution chain.

- 4. Additionally, aluminum is lightweight and durable compared to alternative materials, reducing transportation costs and minimizing environmental impact.

Printed Aluminum Sheet For Closure Caps not only has good deep drawing forming performance and low anisotropy, but also has certain baking strength after multiple color registration and curing.

Printed aluminum bottle cap materials are widely used in various packaging materials such as wine bottles, beverage bottles, and medicinal bottles.

We provide Printed Aluminum Sheet For Closure Caps with various graphics and text, and can customize production according to customer requirements. The pattern is clear and beautiful. The paint used is food grade, bisphenol A-free, and has FDA and SGS certification.

Specifications of Printed Aluminum Sheet for Closure Ropp Caps

| Product Name | Printed Aluminum Sheet For Bottle Cap |

| Alloy | 8011 Aluminum Alloy |

| Temper | H14, H16 |

| Thickness | 0.15-0.25mm |

| Type | Sheet |

| Surface Treatment | One side color print, the other side transparent clear protective lacquer. In complete print sizes and sorts, with clear and beautiful pattern. High temperature resistant without any distortion and color change. |

| Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

| MOQ | 1-3 ton per size |

| Packaging | Export wooden stronger boxes |

| Delivery Time | 25-30 days after order and deposit |

| Alloy | 8011 3105 |

| Temper | H14, H16, H24, H26 |

| Thickness | 0.15~0.25 mm (+/-0.005mm) |

| Width | 400~1000 mm (+0.5mm, -0mm) |

| Length | 400~1000 mm (+0.5mm, -0mm) |

Chemical Composition of Printed Aluminum Sheet for Closure Caps

| Alloy | 8011 | 3105 |

| Fe | 0.60~1.0 | 0.7 |

| Si | 0.50~0.9 | 0.6 |

| Cu | 0.1 | 0.3 |

| Mn | 0.2 | 0.3~0.8 |

| Mg | 0.05 | 0.2~0.8 |

| Cr | 0.05 | 0.2 |

| Zn | 0.1 | 0.4 |

| Ni | - | - |

| Ti | 0.08 | 0.1 |

| Other | 0.15 | 0.15 |

| Al | Remain | Remain |

Spectrum of Printed Aluminum Sheet for Bottle Cap

Mechanical Property for CC Materials of Printed Aluminium Sheet for Bottle Cap

| Alloy | 8011 |

| Temper | H14 |

| Thickness (mm) | 0.16-0.23 |

| Ultimate Tensile Strength (Mpa) | 185-205 |

| Elongation (%) | no less than 2 |

| Earring Rate | less than 2% |

Mechanical Property for DC Materials of Printed Aluminium Sheet for Bottle Cap

| Alloy | 8011 |

| Temper | H14 |

| Thickness (mm) | 0.16-0.23 |

| Ultimate Tensile Strength (Mpa) | 125-155 |

| Elongation (%) | no less than 2 |

| Earring Rate | less than 2% |

ROPP Cap closure Printed aluminum sheet applications

The main uses include manufacturing filling caps, bottle caps, lids and various bottle packaging seals. Through deep processing of the surface of the aluminum plate, such as spray coating or DOS oil pre-treatment, it also has the characteristics of high temperature resistance and corrosion resistance to ensure that the aluminum substrate is completely isolated from food.

- In the pharmaceutical industry, ensuring the safety and authenticity of medicines to meet regulatory requirements and consumer expectations.

- In the beverage industry, ROPP bottle caps feature vibrant printed designs that increase brand awareness and consumer engagement.

- In the cosmetics industry, aesthetically pleasing bottle caps contribute to product differentiation and premium branding.

According to market demand and different uses, some large enterprises usually require a large amount of capping and sleeve materials, and the demand for ROPP capped printed aluminum plates is also relatively high.

ROPP Cap closure Printed aluminum sheet manufacturing process

The manufacturing process of ROPP capped printed aluminum sheets involves multiple steps to ensure precision and quality.

- 1. Clean and treat the aluminum plate to remove any impurities that may affect printing and adhesion.

- 2. Apply the primer coating using techniques such as roller coating or spraying.

- 3. Transfer the printed design to the primed surface using advanced printing methods such as offset or digital printing.

- 4. Apply a protective coating to increase the service life of the printed aluminum plate.

ROPP lid closure printed aluminum panels represent the fusion of advanced sealing technology and beautiful packaging design, providing multiple benefits to manufacturers, brand owners and consumers alike. With tamper-resistant features, customizable printing options and barrier properties, these innovative packaging solutions are well-positioned to meet the changing needs of diverse industries such as pharmaceuticals, beverages and cosmetics.