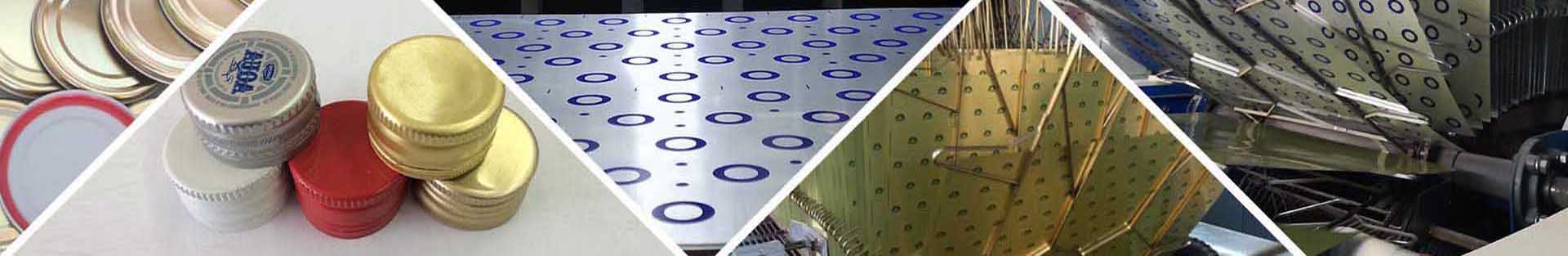

1060 aluminum coil strip for vial seals

Aluminum bottle seals play a vital role in pharmaceutical packaging, ensuring the integrity and safety of pharmaceuticals. Among the various alloys available, 1060 aluminum stands out as a popular choice for manufacturing tape and roll used for vial sealing. Known for its excellent formability, corrosion resistance and compatibility with sterilization processes, 1060 aluminum provides pharmaceutical companies with a reliable solution for safely sealing vials.

Composition and properties of 1060 aluminum

1060 aluminum belongs to the commercial pure aluminum series and contains 99.6% aluminum as the main alloying element.

It is characterized by high electrical conductivity, thermal conductivity and solderability, making it suitable for a wide range of applications beyond vial sealing, such as electronics and construction.

The absence of important alloying elements provides excellent corrosion resistance, especially in environments where chemical exposure is a concern.

1060 aluminum offers excellent formability, allowing manufacturers to achieve the complex shapes and precise dimensions required for vial sealing.

Specifications of 1060 aluminum sheet strip and foil for vial seals

| Alloy | 1060 |

| Temper | O, H22, H24 |

| Thickness | 0.15-0.5mm or as required |

| Width | 500-2500mm |

| Length | Customized |

| Tolerance | ±1% |

| Use | Aluminum liquid caps, anti-theft bottle caps, cosmetic bottle caps, oral liquid aluminum-plastic composite caps, infusion bottle aluminum-plastic caps, etc. |

| Delivery time | 20-25 days |

| Packing | Export fumigated wooden frame or wooden case fine packing or as required |

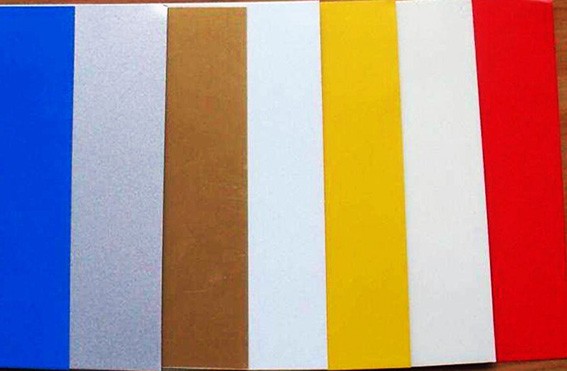

1060 aluminum coil strip for vial seals surface type

Haomei Aluminum can provide gold, white, red, blue, black, single-sided color, double-sided painted and other primary color aluminum strips, painted aluminum strips, and coated aluminum strips.

- Ordinary calendered aluminum strip

- DOS oil lubricated surface treatment

- Chrome surface treatment

- One side is gold/white/red/blue/black and other colors, and the other side is protective paint

- Varnish/clearcoat on both sides

Advantages of 1060 aluminum tape for vial sealing

A. Excellent formability

The superior ductility of 1060 aluminum allows it to precisely conform to the contours of a vial opening without cracking or tearing.

This formability facilitates a tight seal, preventing contamination and maintaining the efficacy of the drug product.

B. Corrosion resistance

The purity of 1060 aluminum gives it inherent corrosion resistance, ensuring vial seal integrity even under harsh storage conditions.

Pharmaceutical companies can rely on 1060 aluminum seals to maintain product purity throughout shelf life.

C. Compatibility with sterilization processes

Vial seals made from 1060 aluminum can withstand a variety of sterilization methods, including autoclaving and gamma irradiation, without affecting their mechanical properties.

This compatibility ensures that pharmaceutical products remain sterile and safe for patient use, meeting regulatory requirements.

Earring of 1060 aluminum sheet strip and foil

| Temper | Earring |

| O | ≤6% |

| H22 | ≤5% |

Mechanical properties of 1060 aluminum sheet strip and foil

| Alloy | 1060 | 1060 |

| Temper | O | H22 |

| Thickness(mm) | 0.15~0.5 | 0.4~0.5 |

| Tensile strength (Rm/Mpa) | 55~95 | 75~110 |

| Elongation (%) | 15/18 | 6 |

| Earring rate (%) | ≤6 | ≤5 |

Thickness tolerance of 1060 aluminum sheet strip and foil

| Thickness mm | Thickness tolerance mm |

| 0.150-0.250 | ±0.005 |

| >0.250-0.500 | ±0.010 |

Width tolerance of 1060 aluminum sheet strip and foil

| Width mm | Width tolerance mm |

| ≤800.0 | +0.5 0 |

| >800.0 | +1 0 |

1060 aluminum coil strip for vial seals manufacturing process

Casting: The manufacturing process begins by casting molten 1060 aluminum alloy into an ingot of specific dimensions.

Rolling: The steel ingot undergoes a hot rolling process to reduce its thickness and reach the specifications required for coiling.

Annealing: Annealing is used to enhance the ductility and formability of the aluminum strip, making it easier to shape during the vial sealing process.

Slitting: Use precision slitting machinery to cut the rolled aluminum coils into narrow strips of uniform width and customize them according to the size of the vial opening.

Surface treatment: Optionally, the aluminum strip can be cleaned, degreased or coated to improve its adhesion and compatibility with the sealing material.

1060 aluminum coil strip for vial seals chemical composition

| Element | Chemical Composition (Weight %) |

| Aluminum (Al) | Minimum 99.60% |

| Silicon (Si) | Maximum 0.25% |

| Iron (Fe) | Maximum 0.35% |

| Copper (Cu) | Maximum 0.05% |

| Magnesium (Mg) | Maximum 0.03% |

| Manganese (Mn) | Maximum 0.03% |

| Zinc (Zn) | Maximum 0.05% |

| Titanium (Ti) | Maximum 0.03% |

| Other Elements | Maximum 0.03% each, with a maximum total of 0.15% |

Applications of 1060 aluminum coil strip in vial sealing

Pharmaceutical industry: 1060 aluminum coil tape is widely used in the pharmaceutical industry to seal vials containing injectable drugs, vaccines and diagnostic reagents.

Medical packaging: used in the production of sterile packaging for medical devices to ensure the sterility and integrity of the product.

Laboratory Applications: The versatility of 1060 aluminum tape extends to laboratory environments for sealing vials and containers containing chemical reagents and samples.

1060 aluminum tape for vial sealing embodies the synergy of materials science and pharmaceutical packaging to provide a reliable solution for safely sealing pharmaceutical products. With its superior formability, corrosion resistance and compatibility with sterilization processes, 1060 aluminum helps improve the integrity, safety and sustainability of pharmaceutical packaging systems.