3004 Aluminum for Lamp Caps

3004 aluminum alloy is a commonly used material for lamp holders, offering excellent workability and good strength.

The main component of 3004 aluminum alloy is aluminum (Al), with the addition of manganese (Mn) and magnesium (Mg). This composition provides 3004 aluminum alloy with good strength and oxidation resistance, making it highly suitable for use in lamp holder applications.

Features of Lamp Holder Aluminum 3004

- 1. Moderate Strength: Compared to 3003 alloy, 3004 aluminum alloy has higher strength while still maintaining good ductility and formability.

- 2. Good Corrosion Resistance: Due to its manganese and magnesium content, 3004 offers excellent corrosion resistance in environments exposed to air and moisture, which is especially important in lighting applications where moisture or outdoor exposure is common.

- 3. Good Formability and Weldability: This alloy is easy to form through cold working processes and has good weldability, making it suitable for manufacturing complex lamp holder structures.

- 4. Lightweight: Aluminum alloys are lightweight, reducing the overall weight of the lighting fixtures, which facilitates installation and transportation.

Specifications of 3004 Aluminum Strip For Lamp Holder

| Alloy | 3004 |

| Temper | H32, O |

| Thickness | 0.2~0.4mm |

| Width | 20~1000mm |

| Tolerance | Thickness: +/-0.02mm Width: +/-1.0mm |

| Coil ID | 76/152/300/400/500mm |

Chemical Composition of Aluminum Strip For Lamp

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Aluminum | |

| Each | Total | |||||||||||

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | 0.05 | 0.15 | Remains |

Mechanical Property of Aluminum Strip For Lamp Holder

| Temper | Thickness mm | Tensile Strength Rm MPa | Yield Strength Rp0.2 MPa | Elongation % A50mm | Bend Radius | Hardness HBWa | |||

| min. | max. | min. | max. | 180° | 90° | ||||

| O | 0.2-0.3 | 155 | 200 | 60 | 13 | 0t | 0t | 45 | |

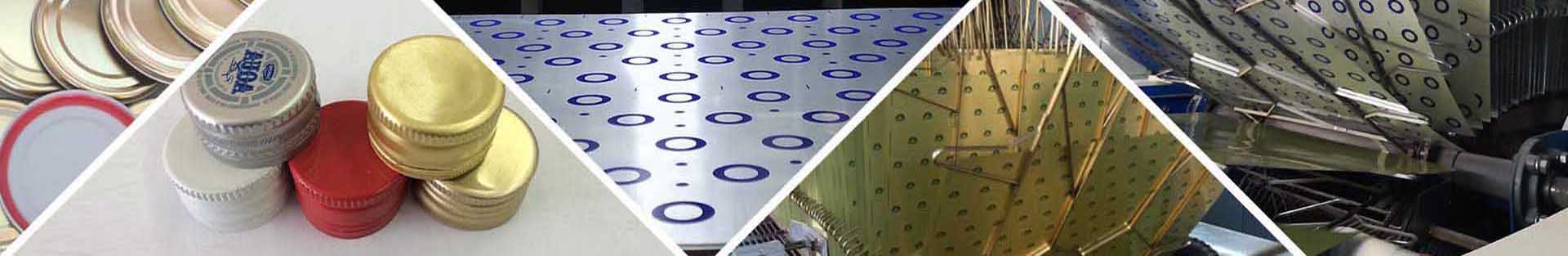

Applications of 3004 Aluminum

3004 aluminum is widely used in the manufacturing of lamp holders and lighting frames, making it particularly suitable for household, commercial, and industrial lighting structures.

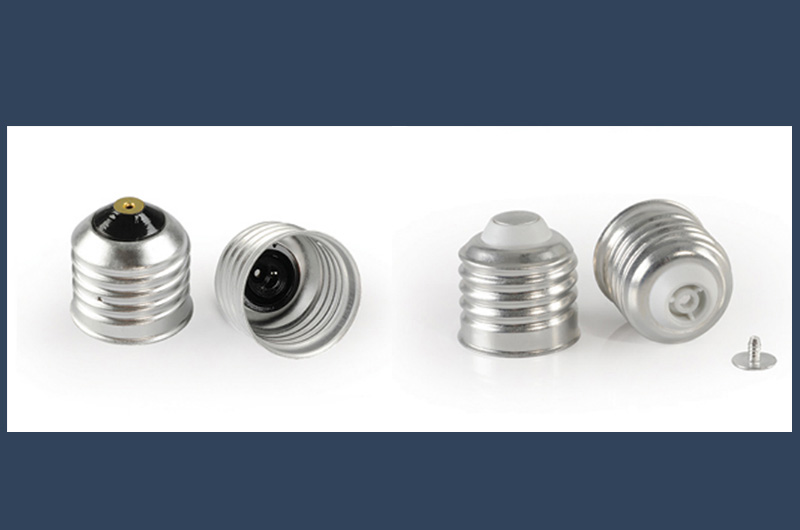

1. Lamp Holder (Base) Manufacturing: Due to its excellent corrosion resistance and moderate strength, 3004 aluminum has become an ideal material for making lamp holders (bases). These characteristics ensure the durability of the lamp holders in daily use, effectively resisting oxidation and corrosion caused by environmental factors while maintaining stable structural performance. 3004 aluminum is extensively used in the production of lamp holders for household lighting, commercial lighting (such as in offices and retail spaces), and industrial lighting (such as high-intensity lighting equipment in factories and workshops). Especially in modern LED and fluorescent lamps, 3004 aluminum can withstand the heat and environmental pressure from long-term use, ensuring the reliability and longevity of the lamp holder components.

2. Lighting Frames and Brackets: The lightweight nature and relatively high mechanical properties of 3004 aluminum alloy make it ideal for manufacturing lighting brackets and frames. This material not only reduces the overall weight of the lighting fixtures, making installation and maintenance easier, but also provides excellent strength while maintaining structural stability. Since lighting frames and brackets often need to bear considerable weight or be frequently adjusted, the moderate strength and workability of 3004 aluminum allow it to meet these demands effectively, making it widely used in modern lighting designs.

3. Broad Lighting Applications: 3004 aluminum is commonly used in the production of various types of lighting fixtures, especially LED and fluorescent lamps, which require high levels of heat dissipation and structural strength. Products such as LED lamp holders and fluorescent lamp frames use 3004 aluminum, ensuring long service life and resistance to external environmental factors like humidity and chemicals. Additionally, its malleability allows designers to flexibly shape the material to fit various lighting designs.

Advantages of Lamp Holder Aluminum 3004

- Cost-effectiveness: 3004 aluminum is relatively inexpensive compared to high-strength aluminum alloys, making it suitable for mass production of lamp holders and other components.

- Eco-friendliness: Aluminum is recyclable, aligning with modern environmental standards and making it popular in the lighting industry.

Processing Methods for Lamp Holder Aluminum 3004

- 1. Extrusion: 3004 aluminum alloy is suitable for extrusion, allowing it to be formed into various shapes and sizes for lamp holder components.

- 2. Stretching and Stamping: This aluminum material has good ductility, making it suitable for stretching or stamping processes to manufacture various lamp holder structural components, especially for applications requiring thin-walled parts.

- 3. Surface Treatment: Lamp holder materials usually undergo anodizing or electroplating treatments to enhance their aesthetic appeal and corrosion resistance.

Due to its strength, corrosion resistance, good formability, and weldability, 3004 aluminum alloy is the ideal material for lamp holder manufacturing.