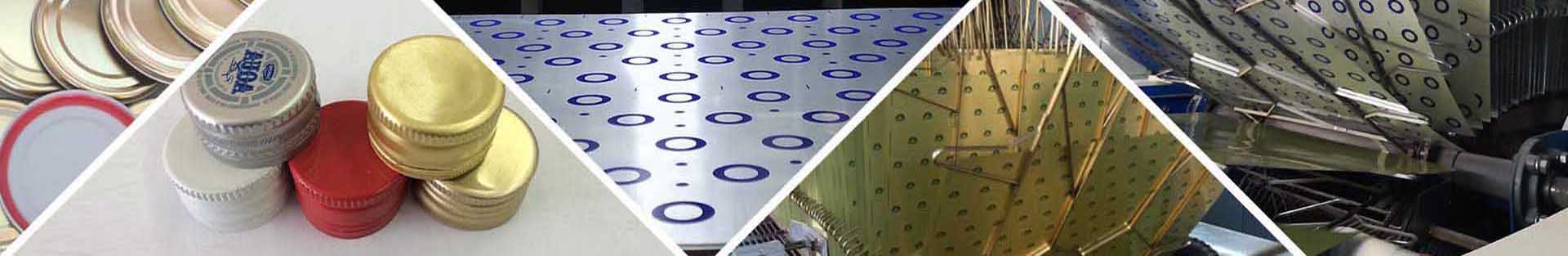

3004 Aluminum for PP ROPP Caps

3004 aluminum alloy is a typical Al-Mn series (aluminum-manganese series) alloy, with excellent formability, corrosion resistance, and moderate strength, making it widely used for manufacturing PP and ROPP bottle caps.

Why is Aluminum Used for Bottle Caps?

- 1. Lightweight: Aluminum has a low density and is lightweight, making aluminum caps significantly reduce the overall weight of packaging, especially reducing costs in transportation and storage.

- 2. Excellent Formability: Aluminum has good ductility and formability, making it suitable for various processing methods such as stamping and rolling, allowing the formation of complex cap structures like tamper-evident rings and threads.

- 3. Corrosion Resistance: Aluminum forms a natural oxide film in the air, providing good corrosion resistance. In particular, for packaging in the food, beverage, and cosmetic industries, aluminum caps do not react with the contents, ensuring product safety.

- 4. Tamper-evident Function: Aluminum can be processed into tamper-evident caps (such as ROPP), where opening the bottle breaks the safety ring, serving an anti-counterfeiting purpose. Additionally, the strength of aluminum is sufficient to withstand repeated opening and closing.

- 5. Easy Coating Treatment: Aluminum bottle caps are easy to surface-treat, such as color coating, lubrication (e.g., DOS oil), chrome plating, or epoxy coating, enhancing their corrosion resistance and aesthetics, meeting brand and market demands.

- 6. Recyclability: Aluminum has high recycling value and can be recycled multiple times, helping reduce the environmental impact of packaging waste. Therefore, in the context of sustainable development, aluminum caps are a more environmentally friendly choice.

Advantages of 3004 Aluminum

- Corrosion resistance ensures the safety and longevity of bottle caps used in food, beverage, and cosmetic industries.

- Formability supports various complex cap designs, such as tamper-evident rings and threads.

- Moderate strength is suitable for sealing the bottle, without excessive hardening or deformation, ensuring product quality.

Haomei Aluminum 3004 aluminum sheet has a smooth surface with no marks or stains, making it suitable for can bodies and can caps. 3004 aluminum cap material has good shape, excellent bending, and deep-drawing performance.

The Specification of 3004 Aluminum For Cap Material

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) | Final Usage |

| 3004 Aluminium Closure Sheet | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38 | 0.2-4.5 | 100-2600 | 500-16000 | bottle caps, can lids, liquid crystal backing material, etc. |

Chemical Properties of 3004 Aluminum For Bottle Cap Material

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al Min |

| 3004 | 0.30 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | 0.25 | 0.25 | 0.05 | 0.15 | Remainder |

Haomei Aluminum has exported aluminum closure sheets to countries such as Japan and South Korea.

Processing Methods of 3004 Aluminum

- 1. Stamping: 3004 aluminum alloy is suitable for cold forming, and through stamping, PP and ROPP caps of different sizes and shapes can be produced.

- 2. Roll Forming: The thread portion of ROPP caps is formed through a rolling process, and the ductility of 3004 aluminum ensures that it will not crack or be damaged during processing.

- 3. Coating and Surface Treatment: Bottle caps are often surface-treated to enhance corrosion resistance and appearance, such as color coating, oiling (e.g., DOS oil lubrication), or chrome plating. 3004 aluminum can withstand these treatments while maintaining excellent performance.

How Thick is a ROPP Cap?

The thickness of a ROPP (Roll-on Pilfer-proof) cap is usually between 0.18 mm and 0.25 mm, depending on the design requirements of the cap, the application scenario, and the type of aluminum alloy used.

The thickness of the cap not only affects its strength and durability but also influences the ductility and forming effect of the aluminum during processing.

3004 aluminum alloy is an ideal material for manufacturing PP and ROPP caps. It not only has excellent processing properties and corrosion resistance but can also enhance aesthetics and protective functions through surface treatments, making it widely used in beverage, cosmetic, and food packaging industries.