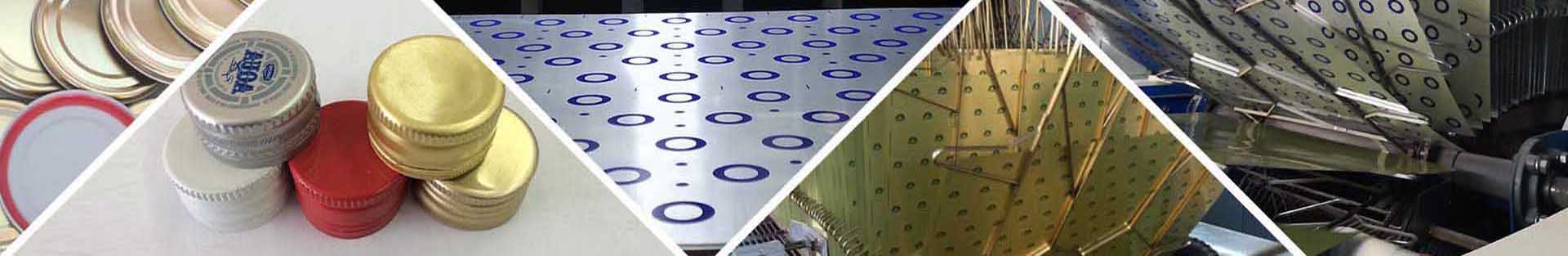

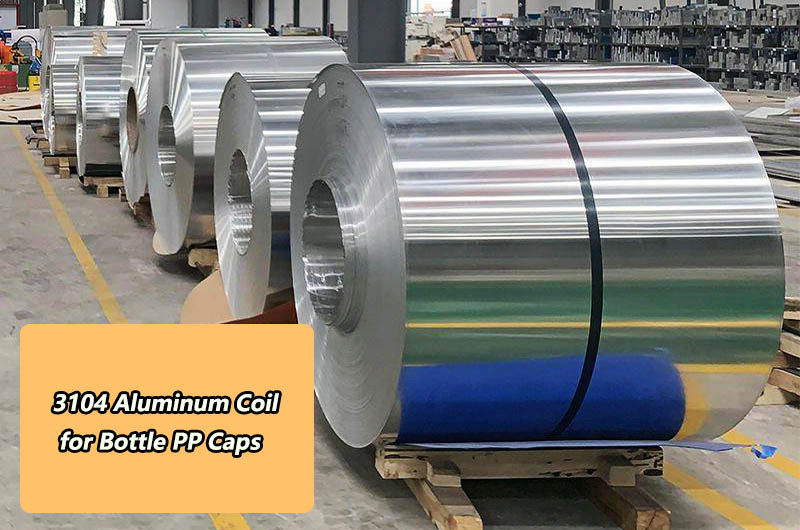

3104 Aluminum Sheet for Bottle PP Caps

3104 aluminum alloy has high strength and excellent processing properties, making it suitable for stamping, forming, deep drawing and other processing processes. This enables the manufactured bottle cap material to have good shape stability and mechanical properties.

3104 aluminum plate is mainly used to produce PP (polypropylene) bottle caps. These lids are commonly found on various types of beverage containers, including bottles for water, soda, juice, and other liquid products.

3104 aluminum cover plate can be said to be an ideal material for the production of bottle caps. It is suitable for both transparent and opaque coatings, and will not bend during the curing process. For long bottle caps that require deep drawing, the ears of Haomei Aluminum aluminum cover plates are very low, which greatly reduces the customer's scrap rate.

Compared with aluminum caps, the cost of plastic bottle caps is about double or more than that of aluminum caps. In contrast, aluminum PP covers have simple structure, strong adaptability and good sealing effect. Not only can brightly colored patterns be printed, but mass production is easy and the cost is low.

3104 aluminum plate is a deformed aluminum alloy with high tensile strength and an elongation of up to 20%. It has good deep drawing performance and is suitable for thinning, stretching and lightweighting to reduce material usage. Each process of cans has strict requirements, and our company strictly controls each process to ensure that the product has appropriate strength and formability.

There are two main types of aluminum alloy sheets used to produce aluminum alloy cans.

- The cover is generally made of 3104, 5182, or 5052 aluminum plates.

- The tank body is made of rust-proof aluminum alloy containing Mn and Mg, generally 3104 alloy.

3104 aluminum closing plate is used in the bottle cap market. Haomei Aluminum uses unique rolling technology to provide aluminum sheets that are ideal for manufacturing long-neck wine bottle caps, ultra-deep drawn and decorative caps, as well as a range of anti-theft caps for beverage bottles, soft drinks, juices, isotonic drinks, energy drinks, etc. Products such as 30 x 60 mm are commonly used in the wine and spirits sector.

3104 aluminum coil is a deformed aluminum alloy with a tensile strength greater than or equal to 275MPA and an elongation of up to 20%. It has good deep drawing performance and is suitable for reducing material usage through thinning, deep drawing, and lightweighting. It has good corrosion resistance, plus excellent weldability, formability and other advantages.

Characteristics of 3104 Aluminum Sheet Coil for PP Caps

- 1. Good corrosion resistance: Aluminum is naturally resistant to corrosion, making it ideal for applications with frequent contact with liquids. This feature ensures that the cap remains intact and does not degrade over time, thus preserving the quality of the bottle's contents.

- 2. Good formability: 3104 aluminum alloy is highly formable and can be easily formed into the desired bottle cap design. This formability enables manufacturers to produce caps in a variety of sizes and configurations to accommodate different bottle types and sealing requirements.

- 3. High strength: Although aluminum is lightweight, its strength is impressive, making the bottle caps durable. This strength ensures the cap effectively seals the bottle, preventing leaks and maintaining product freshness.

- 4. Good heat resistance: Aluminum has good heat resistance, allowing the bottle cap to withstand sterilization processes such as pasteurization or hot filling without deformation or degradation. This is especially important for products that require heat treatment for preservation.

- 5. Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice for packaging materials. The use of 3104 aluminum plate in bottle caps promotes sustainability by facilitating the recycling process and reducing the environmental impact of packaging waste.

3104 aluminum sheet is a reliable and versatile material for manufacturing PP bottle caps, offering corrosion resistance, formability, strength, heat resistance and recyclability. These properties make it ideal for ensuring the integrity and safety of bottled beverages while meeting sustainability goals.

Advantages of 3104 PP Bottle Cap Aluminum Plate

- Light weight.

- Recycling is easy and economical.

- Has superior barrier properties.

- Has good formability.

- It provides a bright finish to the decor.

On the one hand, 3104 aluminum is stable in nature and does not easily react with the products it contains, ensuring the safety of food and beverages.

On the other hand, 3104 material is lighter, and its advantage is that sealed containers made from it can be lighter and easier to transport, saving costs.

With the upgrading of can production technology, the requirements for the surface performance of 3104 aluminum plates are getting higher and higher. Haomei Aluminum continues to invest in the research and development and upgrade of 3104 can aluminum coil processing technology to ensure that the quality of the alloy used by customers is at high market standards.

Haomei Aluminum's closed sheets are rolled to very tight tolerances, producing more closed sheets per ton of raw material and allowing high-speed multi-chamber presses to operate without interruption. Its strength, high formability, low lug and printable surface make it ideal for tamper-evident caps and vial seals.

Aluminum Sheet for PP Caps

When aluminum is used in PP (polypropylene) bottle caps, the aluminum usually takes the form of a foil or liner that is integrated into the cap design.

The purpose of adding aluminum to PP bottle caps may vary:

- 1. Seal integrity: When a lid is placed on a bottle, an aluminum liner or foil provides a tight seal that helps prevent leaks and maintain product freshness.

- 2. Tamper-proof: Aluminum liners can be designed with tamper-proof features, such as a foil seal that must be broken when the bottle is first opened. If the seal has been broken, it is an indication that the product may have been tampered with.

- 3. Barrier properties: Aluminum has excellent barrier properties against moisture, oxygen and other contaminants, helping to protect the contents of the bottle from external factors that may affect its quality or shelf life.

- 4. Compatibility: Aluminum is compatible with a variety of products, including beverages, pharmaceuticals, and food, making it a versatile choice for bottle cap liners.

Aluminum sheet plays a vital role in the production of PP bottle caps, with its comprehensive properties suitable for sealing and preserving bottle contents in various industries.

8011 3105 3104 Aluminum sheets are often used to make PP (polypropylene) bottle caps because of their excellent properties such as light weight, corrosion resistance, and suitability for molding processes. PP caps are widely used in the packaging industry to seal bottles containing various liquids such as beverages, pharmaceuticals and chemicals.

| Alloy | 8011/3105/3104 |

| Temper | H14, H16, H24, H26 |

| Thickness | 0.15~0.25 mm(+/-0.005mm) |

| Width | 500~1000 mm(+0.5mm, -0mm) |

| Length | 500~1000 mm(+0.5mm, -0mm) |

| Coil | 500~1000 mm |

| Strip | 20~500 mm |

| Earing | 1 |

| Diagonal | ≤ 1mm |

- Surface Treatment: The surface of aluminum panels is often treated to enhance its appearance and performance. This may include processes such as cleaning, degreasing and surface coating to provide better bonding to the PP material during the cap forming process.

- Forming process: The Aluminum sheet used for PP bottle caps undergoes deep drawing and other forming processes to shape it into the desired cap shape. The material's properties, including ductility and ductility, are critical to successful molding without causing defects.

- Sealing: Aluminum lids provide an effective seal, preventing leaks and ensuring product freshness. Aluminum's compatibility with various sealing liners is an important consideration in bottle cap design.

- Printing and Decoration: Aluminum covers can be decorated with printing, embossing or other surface treatments to convey branding, product information or aesthetic appeal.

- Quality Standards: PP Aluminum Sheet for Bottle Caps manufacturers adhere to industry standards and regulations to ensure product quality, consistency, and safety. This may include adhering to specifications such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

Haomei Aluminum - Trusted Aluminum Sheet/Coil/Strip/Foil Aluminum For Closure Caps Suppliers

Haomei is committed to the research and development and production of aluminum caps materials such as PP caps, ROPP caps, screw caps, wine caps, vial seal etc. With a complete production system and numerical control equipment, the quality of the end product is controllable and the price is reasonable.

Chemical Composition of 3104 Aluminium Sheet for PP Bottle Cap

| Alloy | 3104 | |

| Fe | 0.7 | |

| Si | 0.6 | |

| Cu | 0.3 | |

| Mn | 0.3~0.8 | |

| Mg | 0.2~0.8 | |

| Cr | 0.2 | |

| Zn | 0.4 | |

| Ni | - | |

| Ti | 0.1 | |

| Other | Each | 0.05 |

| Total | 0.15 | |

| Al | Remains | |

Mechanical Property for Direct Casting

| Alloy | 3104 |

| Temper | H14 |

| Thickness (mm) | 0.15~0.25 |

| U.T.S (Mpa) | 150~200 |

| Elongation (%) | ≧1 |

3104 Aluminum Sheet for Bottle PP Caps Tolerance

| Alloy | 3104 alloy for pop can lid |

| Temper | H19 |

| Mechanical properties | UTS: 270-320 MPa TYS: 230-280 MPa EL: ≧5% |

| Thickness and tolerance (mm) | 0.20-0.36 (+0.003, -0.003) |

| Width and tolerance(mm) | 800-1730 (+1.0, -0) |

| Coil ID(mm) | 405 or 505 (+0.5, -0.5) |

| Coil OD(mm) | 1300-1800 |

Applications of 3104 aluminum PP closure sheet

Because 3104 aluminum alloy has good processing properties and corrosion resistance, it is widely used in the manufacture of various types of bottle cap materials, including beverage bottles, pharmaceutical bottles, cosmetic bottles, etc. They can be part of an aluminum cover or a plastic/aluminum composite cover.

The following are common applications of 3104 aluminum PP closed plates

Wine bottle caps, beverage bottle caps, soft drinks, juices, isotonic drinks, energy drink caps, cosmetic caps, can caps, vial sealing caps, tear-off sealing caps, reversible vial seals, aluminum caps, pharmaceutical caps, pull-off caps Type aluminum cap, injection bottle cap, injection bottle cap.

3104 aluminum plate for beverage pp bottle caps

Temper: H19

Specifications: The thickness is usually between 0.18mm and 0.25mm, and the width varies according to the bottle mouth size, usually ranging from 300mm to 500mm.

3104 Aluminum Sheet for pharmaceutical PP bottle caps

Temper: H14

Specifications: The thickness is generally between 0.2mm and 0.3mm, and the width varies according to the size of the bottle mouth, usually ranging from 200mm to 400mm.

3104 Aluminum Sheet for cosmetic PP bottle caps

Temper: H16

Specifications: The thickness is usually between 0.15mm and 0.25mm, and the width varies according to the bottle mouth size, usually ranging from 200mm to 400mm.

3104 Aluminum Sheet for food can PP bottle caps

Temper: H24

Specifications: The thickness is generally between 0.25mm and 0.35mm, and the width varies according to the size of the can mouth, usually ranging from 300mm to 600mm.

3104 Aluminum Sheet for industrial PP bottle caps (such as chemical products)

Temper: H18

Specifications: The thickness is usually between 0.3mm and 0.5mm, and the width varies according to the bottle mouth size, usually ranging from 400mm to 800mm.

Aluminum Sheet for PP Caps Related Tags

- 3104 Aluminum Sheet for Bottle PP Caps

- 3104 aluminum closure sheet

- 3104 Aluminum for Pop Cans

- 3104 Aluminum Coil for the Can and Bottle Cap material

- Aluminium Coil 3004/3104 For Can Body

- pp cap stock material usually use 3104 aluminum

- Can lid (bottom) material 3104-H19

- Can lid 3104 alloy aluminum plate

- Food can lid material 3104-H19 aluminum plate

- Anti-theft bottle cap material 3104 aluminum plate

- 3104 h48 aluminum coil for food can can lids