3105 Aluminum Sheet Coil for Closure

3105 aluminum coil has become a common material widely used in bottle cap manufacturing due to its excellent corrosion resistance, formability and weldability. From beverage and food containers to industrial applications, caps made from 3105 aluminum offer reliability, safety and aesthetics to meet the diverse needs of various industries.

- 3105 aluminum alloy is a deformed aluminum-manganese alloy with excellent corrosion resistance and formability properties.

- It belongs to the 3000 series of aluminum alloys, known for its versatility and wide range of applications.

- The main alloying element of 3105 aluminum is manganese, which enhances its strength and corrosion resistance.

3105 aluminum plates are widely used in various fields, including the production of screw caps, PP caps, beverage cans and other products. Especially when packaging carbonated drinks, 3105 alloy bottle caps are an indispensable choice. In addition, it is widely used in the manufacture of cosmetic bottle caps.

In order to enhance the performance of 3105 aluminum spiral cover plates, we have taken measures such as phosphate chromate treatment and DOS coating treatment. At the same time, on the basis of plain boards, we can also realize printing in a variety of different colors to meet the personalized needs of customers.

The 3105 aluminum plate used for bottle caps has good anti-rust properties and good deep drawing effect. The strength, elongation and processing performance of the aluminum plate can meet the high-intensity automated bottle cap production process, and there will be no creases or cracks during the processing. Ideal for making caps for wine bottles, beverage bottles, soft drinks, juices, energy drinks and high-end cosmetics.

3105 aluminum alloy has good anti-rust properties and can be used in various bottle caps to achieve long-term beautiful appearance of bottles and cans;

Bottle cap material 3105 aluminum sheet meets the processing requirements of aluminum bottle caps

- 1. Excellent anti-rust performance and deep drawing effect: 3105 aluminum sheet belongs to the 3 series aluminum-manganese alloy, which makes it excellent in making bottle caps. It has good anti-rust properties and can maintain a good effect during the deep drawing process to ensure the quality of the bottle cap.

- 2. Strong processing performance: The strength, elongation and processing performance of 3105 aluminum sheet are excellent, which makes it suitable for automated production processes, especially in the manufacturing process of bottle caps that require higher strength.

- 3. Avoid creases and cracks: When using 3105 aluminum sheet to process bottle caps, there will be no problems such as creases or cracks, which ensures the integrity and appearance of the bottle caps.

- 4. Smooth and flawless: The surface of 3105 aluminum bottle cap material is smooth without roller marks or oil spots, which makes subsequent printing work easier and ensures the clarity and legibility of the printed pattern.

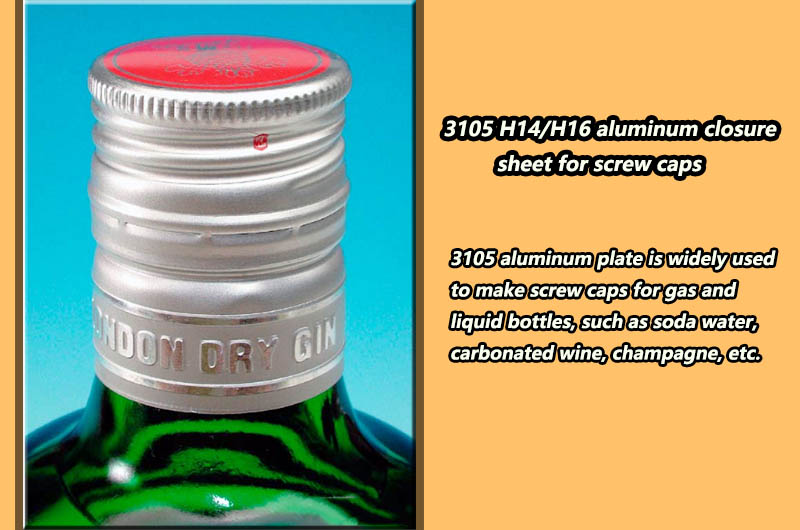

Compared with 8011 aluminum cover plate, 3105 H14 H16 aluminum cover plate has sufficient strength and therefore can withstand gas pressure. Widely used in the production of carbonated drinks and mineral water caps.

Compared with 8011 bottle cap aluminum plate, 3105 screw cap aluminum plate has sufficient strength and can withstand greater gas pressure. 3105 aluminum plate is widely used to make screw caps for gas and liquid bottles, such as soda water, carbonated wine, champagne, etc. In addition, after being treated with chromium phosphate or DOS coating, the 3105 bottle cap aluminum plate can be printed in different colors and decorated with different styles of wine bottle caps and other bottle caps.

3105 bottle cap material can be used for large-area fine printing, multi-color printing, side roller printing, etc. The colors are easy to match, have good saturation and high gloss. In addition, the cost is low and the food safety is good.

Haomei Aluminum can perform phosphate chromate treatment and DOS oil lubricating coating treatment on 3105 bottle cap aluminum sheets, and print different colors on ordinary aluminum sheets. We produce the optimal 3105 aluminum cover material by controlling the material composition, rolling temperature and time, and annealing temperature to meet customers' performance needs, such as opening capacity and earring rate.

The Specification of 3105 Aluminum for Closure Caps

| Alloy | 3105 Aluminum Alloy |

| Temper | H14, H16, H24, H26, H44, H46 |

| Thickness | 0.15-0.45mm |

| Type | Sheet/Coils/Foils/Strips |

| Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

| Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

| MOQ | 1-3 ton per specification |

| Packaging | Export wooden stronger boxes |

The painted aluminum coils for PP bottle caps produced by Haomei Aluminum undergo Dos oil treatment and spray painting process. Haomei Aluminum has developed painted aluminum coils for closing PP lids. The product has high quality, better deep drawing performance, high strength, beautiful appearance, and food-grade safety. The hot selling aluminum for closing PP lids is 3105 aluminum closing sheet.

During the processing of aluminum bottle caps, there are strict requirements on the strength, elongation and dimensional deviation of the painted aluminum coil that closes the PP cap material, otherwise cracks or creases will appear during the processing.

3105 Aluminum for Closure Caps Specification Tolerance Range(mm)

| Thickness | 0.15-0.48mm | ||

| Thickness Tolerance | -/+ 0.01mm | ||

| Width Tolerance | ≤500mm | -/+ 1mm | |

| >500mm | -/+ 2mm | ||

| Length Tolerance | -0/+1mm | ||

| Diagonal Tolerance | ≤1mm | ||

| Flatness | ≤5mm/2m | <3 waves/m | |

3105 Aluminum Sheet Coil for Closure Mechanical Properties

| Alloy | Temper | Thickness(mm) | Tensile strength (Rm/Mpa) | Elongation(%) | Earing ratio (%) |

| 3105 | H14, H24 | 0.2-0.5 | 150-200 | 2 | 4 |

| 3105 | H16, H26 | 0.2-0.5 | 175-225 | 1 | 4 |

| 3105 | H18 | 0.2-0.5 | ≥195 | 1 | 4 |

Earring of 3105 aluminum sheet for bottle caps

| Temper | Earring |

| H14 | ≤3% |

| H24, H16, H26, H18 | ≤4% |

Unevenness of 3105 aluminum sheet for bottle caps

| Thickness mm | 0.150-0.250 | >0.250-0.500 | ||

| Longitudinal unevenness | Wave height mm | not more than | 2 | 3 |

| Wave per meter length | 4 | 3 | ||

| Horizontal unevenness | Wave height mm | 1.5 | 1.5 | |

| Wave height mm | 2 | 2 | ||

3105 Aluminum Sheet Coil for Closure Performance

- Corrosion Resistance: 3105 aluminum has excellent corrosion resistance, making it suitable for use in a variety of environments, including those with high humidity or exposure to chemicals.

- Formability: The alloy has excellent formability, allowing it to be easily shaped, bent and formed into a variety of closed designs without compromising its structural integrity.

- Strength: While not as strong as some other aluminum alloys, 3105 provides sufficient strength for enclosed applications, ensuring durability and long-term performance.

- Weldability: 3105 aluminum can be easily welded using various techniques, thus facilitating the manufacturing process in bottle cap manufacturing.

- Surface Treatment: It can be easily coated or painted to achieve desired aesthetic or functional properties, such as enhanced durability or UV resistance.

Advantages of 3105 aluminum plate for bottle caps

- 1. It has good tensile properties, ear-making rate and corrosion resistance.

- 2. There are no defects such as cracks, bubbles, indentations, light and dark streaks on the surface.

- 3. Width and thickness tolerances must be strictly implemented as required.

- 4. Its strength, high formability, low earring and printable surface make it ideal for anti-theft caps and vial seals.

- 5. Suitable for sealing wine, cosmetics and beverages, especially suitable for sealing long-neck wine bottles.

- 6. Good tolerances enable our sealing plates to produce higher output per ton.

- 7. Light, bright and economical to recycle.

- 8. Compared with plastic bottle caps, aluminum bottle caps not only have better performance, but are also low-cost and pollution-free.

3105 aluminum plate coil surface treatment

3105 aluminum spiral cover plates can be phosphate chromated and DOS coated, and printed with different colors on the basis of our plain plates.

- Ordinary calendered aluminum strip.

- DOS oil lubricated surface treatment.

- Chrome plated.

- One side is gold, white, red, blue, black, etc., and the other side is protective paint.

- Double coated varnish/clearcoat.

The Chemical Composition of Aluminum for Closure Caps 3105

| Alloy | 3105 |

| Fe | 0.7 |

| Si | 0.6 |

| Cu | 0.3 |

| Mn | 0.3-0.8 |

| Mg | 0.2-0.8 |

| Cr | 0.2 |

| Zn | 0.4 |

| Ni | |

| Ti | 0.1 |

| other | 0.15 |

| Al | Remain |

Applications of 3105 aluminum plate coils in bottle cap manufacturing

3105 aluminum caps have been widely used in the sealed packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc.

- 3105 H14/H16 aluminum closure sheet for screw caps: Due to its sufficient strength, 3105 H14 H16 aluminum closure sheet can withstand gas pressure, so it is widely used in making screw caps for carbonated drinks and mineral water.

- 3105 DC Printed Aluminum Sheet for Screw Caps: 3105 DC Printed Aluminum Sheet may be an aluminum sheet made from 3105 alloy, machined using the Direct Chill Cast (DC) casting method. 3105 DC Printed Aluminum Plate for Screw Caps may be a specialty material used in the manufacture of screw caps for bottles or jars that may be printed with a design or message, possibly for branding or identification purposes.

- 3105 Aluminum Coil for Beverage bottle caps: 3105 aluminum is commonly used to produce beverage bottle caps, such as screw caps for bottles and cans. Its corrosion-resistant properties ensure that the closure maintains its integrity even when in contact with acidic or carbonated beverages.

- 3105 Aluminum Coil for Food Container Seals: Due to its non-toxic properties and food-grade compatibility, 3105 aluminum is ideal for manufacturing food container seals, ensuring the safety and freshness of packaged goods.

- 3105 Aluminum Coil for Cosmetic and Pharmaceutical Caps: The formability and aesthetic properties of 3105 aluminum make it suitable for cosmetic and pharmaceutical caps, where precise sealing and visual presentation are critical.

- 3105 Aluminum Sheet for Industrial Caps: From chemical containers to automotive fluid tanks, 3105 aluminum caps are used in a variety of industrial applications where reliability and resistance to harsh environments are critical.

3105 Aluminum Sheet Coil for Closure Manufacturing process

- Cold Rolling: 3105 aluminum alloy is typically produced into sheet or coil through a cold rolling process, which gives the material a uniform thickness and improved surface finish.

- Annealing: Annealing eliminates internal stress and enhances the formability of aluminum coils, ensuring optimal performance during the manufacturing process.

- Surface treatment: Surface treatment processes such as cleaning, degreasing, and chemical conversion coating can be used to prepare the aluminum surface for subsequent coating or printing operations.

- Coating or painting: Depending on application requirements, 3105 aluminum coils may undergo a coating or painting process to enhance corrosion resistance, aesthetics, or other functional properties.

Related popular tags

- 3105 Aluminum for Closure Caps

- 8011/3105 Aluminium Wine Closure Sheet for Screw Caps

- 3105 H14/H16 aluminum closure sheet for screw caps

- Aluminum for Caps Material 3105

- 3105 Aluminium Sheet for Screw Caps

- Aluminum ROPP closures made by 3105 aluminum coil strip

- 3105 h16 aluminum alloy for wine lid material

- 3105 H14 H16 Aluminium Sheet Strip and Foil for Screw Caps

- 3105 Painted Aluminum Coil for Pilproof Caps

- 3105 Aluminum Sheet Coil for Cap Closure

- 3105 aluminum alloy for red wine bottle cap material

- 3105 aluminium closure sheet for screw caps

- High-end cosmetic bottle cap material 3105 aluminum plate

- 3105 printed aluminium closure sheet for bottle cap material

- 3105 Aluminium for Caps Material

- Lacquered 3105 Aluminum Coil for Closure PP Caps