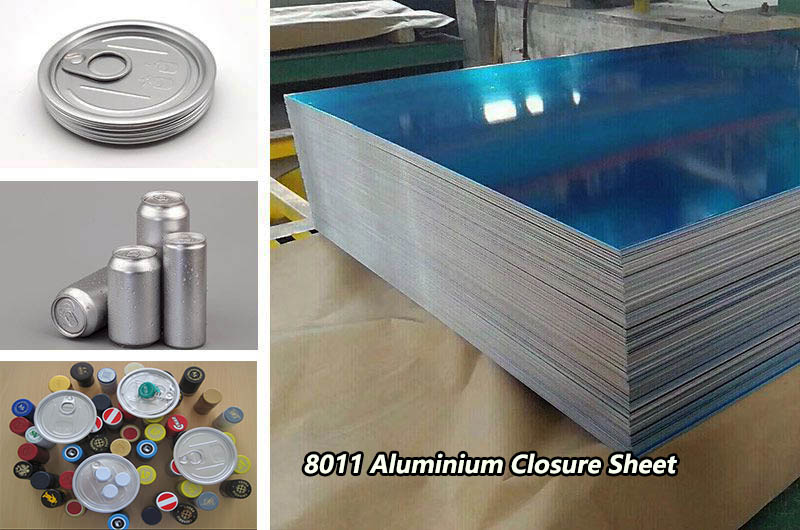

8011 Aluminum for Closure Caps

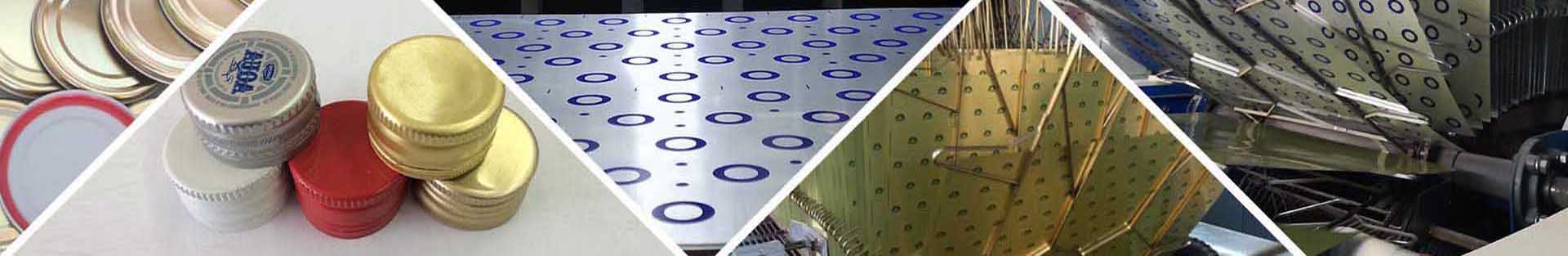

Aluminum bottle caps are often made of 8011 aluminum plate material. 8011 aluminum bottle caps are mainly used for wine, beverages, oral liquids and pharmaceutical and health care products, and can meet special requirements such as high-temperature cooking and sterilization.

The bottle cap is made of aluminum alloy, the grade is 8011, the alloy state is generally H14 and H16, and the hot-rolled deep-drawing process is used. The thickness range is generally 0.15mm to 0.3mm. In order to prevent rust, some manufacturers will require food-grade DOS oil to be applied.

Aluminum caps are very common in daily life, such as wine caps, easy-open caps, pharmaceutical bottle caps, easy-to-tear milk powder caps, etc. They are generally made of 8011 aluminum foil and have good advantages. It has good sealing performance and is easy to open, so it is loved by everyone.

8011 aluminum is a commonly used alloy used in the production of sealing closures for a variety of containers, particularly in the food and beverage industry. A sealing lid is a packaging component that seals a container, such as a bottle or jar, to prevent the contents from leaking or spoiling.

For the processing of capping, there are high requirements for the surface, plate shape, stamping performance, etc. of the material. Aluminum for capping is an ideal material. The most common is 8011 aluminum foil used for capping.

8011 aluminum closure shee has good formability, good earring rate and flatness, so as to make sure the long cap deep drawing. It often used as ROPP caps for wine bottles, and other beverage bottles.

8011 aluminum closing plate is used in the bottle cap market, it is usually used as ROPP caps for wine bottles and other beverage bottles. Haomei Aluminum uses unique rolling technology to provide aluminum sheets that are ideal for manufacturing long-neck wine bottle caps, ultra-deep drawn and decorative caps, as well as a range of anti-theft caps for beverage bottles, soft drinks, juices, isotonic drinks, energy drinks, etc. Products such as 30 x 60 mm are commonly used in the wine and spirits sector.

The greatest qualities of aluminum closing panels are the drawing ability and paint adhesion, guaranteeing the highest quality printing of drawings and designs. 8011 alloy has good formability, good ear forming rate and flatness to ensure the deep drawing of long bottle caps. Commonly used as ROPP caps for wine bottles and other beverage bottles.

8011 aluminum coil is the most widely used aluminum material for bottle caps. It has two main temperaments: H16 and H14. 8011 aluminum coil for bottle caps is an aluminum alloy containing more than 1% iron and silicon. This gives it an advantage among many aluminum alloys.

advantage:

- Best-in-class formability, flatness, squareness and stable surface properties.

- Stable drawing quality ensures the highest material utilization.

- A variety of processes and technologies are available to meet the requirements of various surfaces.

Reasons Why 8011 Alloy is Selected for Aluminum Bottle Caps

8011 aluminum closure plates are used to manufacture screw cap systems for bottles and other containers and are one of the main products in the aluminum packaging market.

8011 aluminum sealing plate foil has good deep-drawing effect, strong mechanical properties, strong puncture resistance, and extremely high light-shielding and barrier capabilities. In addition, 8011 aluminum foil plate also has excellent anti-corrosion and moisture-proof properties. After compounding, printing and gluing, it can be used as aluminum bottle cap sheet.

1. Opaque

Aluminum's airtight and light-tight properties and ease of shaping and decoration make it the material of choice for enclosed applications.

2. 8011 aluminum alloy corrosion resistance

Aluminum 8011 has good corrosion resistance, ensuring that the sealing cap maintains its integrity even when in contact with various substances.

3. Can be molded well

8011 alloy can be easily formed into closures of different shapes and sizes, making it suitable for a variety of packaging applications.

4. Excellent sealing performance

The sealing lid made of 8011 aluminum provides an effective seal, helping to maintain the freshness and quality of the package contents.

5. Lightweight

8011 aluminum is lightweight and is beneficial for packaging applications, helping to reduce transportation costs and energy consumption.

6. Recyclability

Aluminum is highly recyclable, making it an environmentally friendly choice for packaging materials. Sealing caps made of 8011 aluminum can be recycled repeatedly without losing their properties.

8011 aluminum is a versatile and reliable closure material that meets the packaging industry’s stringent requirements for performance, cost-effectiveness and sustainability.

8011 Closure Aluminium Sheet Specifications

- Temper: H14, H16, H24, H26

- Thicknes: 0.15~0.25 mm (+/-0.005mm)

- Width: 500~1000 mm (+0.5mm, -0mm)

- Length: 500~1000 mm (+0.5mm, -0mm)

- Coil: 500~1000 mm

- Strip: 20~500 mm

- Diagonal: ≤ 1mm

- Direct cast (DC) / hot rolled: for long caps (up to 60 mm)

- Continuous Casting (CC) / Cold Rolling: for short caps

- Finished product: Milling, DOS, Painting, Chromating

- Shape: sheet/roll/strip (size is based on customer’s specific requirements)

The 8011 aluminum plate used for bottle caps has a clean and smooth surface, excellent heat insulation and moisture-proof properties, strong puncture and punch resistance, and is hygienic to use. Haomei Aluminum sealing sheets are available in widths from 330mm to 1000mm, with a width tolerance of 1mm. There are no obvious roller marks, black lines, oil spots, ashes, scratches or bright stripes on the surface of the plate, and the ear-making rate is controlled within 3%.

- Direct cast (DC) / hot rolled: for long covers (up to 60 mm)

- Continuous Casting (CC) / Cold Rolling: for short caps

- Finished product: Milling, DOS, Painting, Chromating

- Shape: sheet/roll/strip (size is based on customer’s specific requirements)

Characteristics of 8011 aluminum foil

8011 aluminum foil for bottle caps has excellent moisture resistance, light shielding and high barrier properties. It has a smooth surface, uniform color, no spots, high elongation, good sealing and excellent printing effect. It is a commonly used raw material for bottle cap manufacturers.

- 1. Alloy properties. 8011 aluminum sealing foil belongs to the 8 series alloy Al-Fe-Si aluminum foil. Its alloy element content accounts for more than 1% of the total alloy elements, and its alloy properties also have high advantages.

- 2. Draw deeply. 8011 aluminum sealing foil is not prone to cracks and other defects after stamping deformation.

- 3. Mechanical properties. 8011 aluminum plate tensile strength: 125~165Mpa, yield strength: 110Mpa, elongation: 2~5%.

- 4. Oxidizing property. 8011 aluminum sealing foil has excellent oxidation effect. After oxidation coloring, the color is bright and beautiful.

- 5. Lightweight and environmentally friendly. The specific gravity of 8011 aluminum foil is 1/10 of tinplate. 8011 aluminum foil has the advantages of high recycling and environmental protection, so it is accepted by more manufacturers and customers.

8011 Aluminum for Closure Caps Surface Type

- A. Ordinary calendered aluminum

- B. DOS oil lubricated surface treatment

- C. Chrome plating surface treatment

- D. One side is gold/white/red/blue/black and other colors, and the other side is protective paint

- E. Two-sided varnish/transparent paint

Chemical Composition of 8011 Aluminium Closure Sheet

| Alloy | 8011 | |

| Fe | 0.60-1.0 | |

| Si | 0.50-0.9 | |

| Cu | 0.1 | |

| Mn | 0.2 | |

| Mg | 0.05 | |

| Cr | 0.05 | |

| Zn | 0.1 | |

| Ni | – | |

| Ti | 0.08 | |

| Other | Each | 0.05 |

| Total | 0.15 | |

| Al | Remain | |

Earring of Aluminium for Caps Material 8011

| Temper | H14, H24, H16, H26, H18 |

| Earring | ≤3% |

Unevenness of Aluminium for Caps Material 8011

| Thickness mm | Longitudinal unevenness | Horizontal unevenness | ||

| Wave height mm | Wave per meter length | Wave height mm | Wave height mm | |

| not more than | ||||

| 0.150-0.250 | 2.0 | 4 | 1.5 | 2 |

| >0.250-0.500 | 3.0 | 3 | 1.5 | 2 |

Mechanical properties of Aluminium for Caps Material 8011

| Temper | Thickness mm | Mechanical properties | |

| Tensile strength MPa | Elongation % | ||

| Not less than | |||

| H14, H16 | 0.150-0.500 | 130-165 | 1 |

| H24 | 0.150-0.200 | 125-165 | 2 |

| >0.200-0.500 | 3 | ||

| H26 | 0.150-0.200 | 130-165 | 1 |

| >0.200-0.500 | 2 | ||

| H18 | 0.200-0.500 | ≥165 | 1 |

| Alloy | 8011 |

| Temper | H14 |

| Thickness (mm) | 0.15-0.25 |

| U.T.S (Mpa) | 185-205 |

| Elongation (%) | ≧2 |

Applications of 8011 Closure Aluminium Sheets/Coils

Aluminum closure sheets/coils for the bottle cap market. Customers use our aluminum sheets to manufacture long-neck wine bottle caps, as well as a range of tamper-evident caps for beverage bottles, soft drinks, juices, isotonic drinks, energy drinks and other products. ROPP caps, PP caps, roll anti-theft caps, aluminum anti-theft caps, anti-theft caps, aluminum bottle caps, aluminum screw caps, tear-off caps, flip caps.

The hardness of 8011 sheet is h14 and h16, and it can be made into bottle caps and caps for medicine bottles, spirits, wine, juice, milk powder, tea, etc. The plate can be mass-produced through cold rolling or hot rolling, and has the characteristics of simple process, zero pollution, high recovery rate, and easy deep processing.

Aluminum caps are very common in daily life, such as wine caps, easy-open caps, pharmaceutical bottle caps, easy-to-tear milk powder caps, etc. They are generally made of 8011 aluminum foil and have good advantages. It has good sealing performance and is easy to open, so it is loved by everyone. 8011 aluminum foil for bottle caps has excellent moisture resistance, light shielding and high barrier properties. It has a smooth surface, uniform color, no spots, high elongation, good sealing and excellent printing effect. It is a commonly used raw material for bottle cap manufacturers.

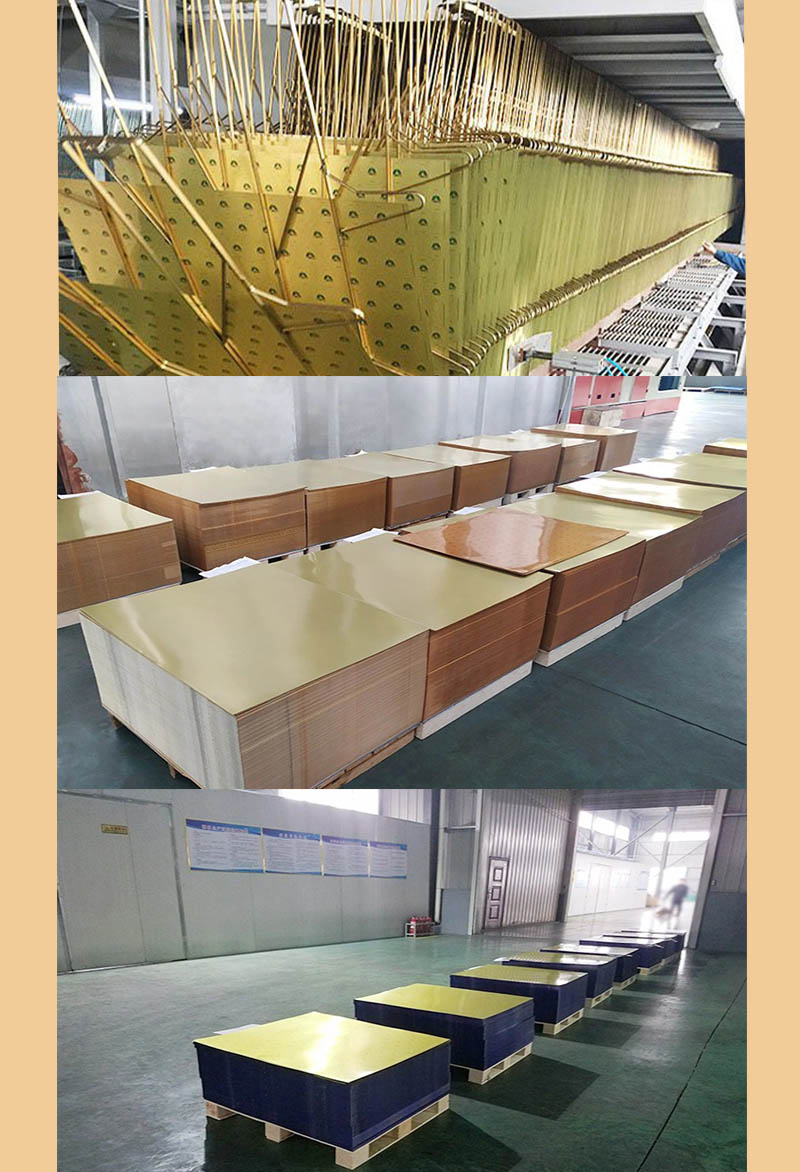

Aluminium for Caps Material 8011 Detailed Picture Display

8011 Aluminum for Closure Caps Applications

8011 Aluminum for Closure PP Caps: 8011 aluminum alloy is a closure commonly used in the production of PP (polypropylene) bottle caps. 8011 aluminum PP bottle caps are widely used in various industries to seal containers, bottles and jars due to their excellent chemical resistance and durability. 8011 aluminum bottle caps effectively block moisture, oxygen and other contaminants, helping to maintain the freshness and quality of package contents.

8011 Aluminum for Injection bottle sealing: Medical injection bottles are sealed with aluminum closing sheets and rubber stoppers through the capping and closing process. 8011 aluminum sealing foil has good tensile processing properties and can fit the rubber stopper well to achieve ideal sealing for injection bottles. Mingtai strictly produces zero-impurity 8011 aluminum sealing foils to stabilize its internal crystal structure and reduce the occurrence of aluminum glands during the later gland sealing process.

8011 Aluminum for Omnia can lid: Haomei produces 8011-H16 aluminum closure foil that meets the EN573-3 standard. The surface is smooth, clean, no spots, no pinholes, and the color is uniform. Therefore, the 8011 aluminum foil used in Omnia can lids has excellent moisture-proof sealing properties, light-shielding properties and extremely high barrier capabilities. Coupled with the extremely high acid resistance and corrosion resistance of 8011 aluminum foil, it can be safely used as omnia can lids for carbonated and other beverages.

8011 Aluminum Closure Sheet For Wine Bottle Caps: 8011Aluminum CLOSURE Sheet for Wine Bottle Caps has a good deep punching performance, which makes the 8011 Aluminum Wine Bottle Caps produced by Haomei Aluminum. Losure's maximum punching depth can reach 60-80mm, and the lid can be poured directly Forever meets the design requirements of different bottlenecks.

Our common wine screw caps and injection bottle seals are all made of 8011 aluminum foil. Of course, in the hot summer, the omnia can lids of our favorite carbonated drinks are all made of 8011-H16 aluminum foil. In the H16 state, it meets the mechanical properties required for the production of omnia can lids, and further optimizes the peeling corrosion resistance of the 8011 aluminum closure foil for omnia can lids.

other apps

- 1) Bottle cap materials: white wine bottle cap, red wine bottle cap, yogurt cap, medical cap, cosmetic cap, etc.

- 2) Drug packaging: PTP medicine foil, cold stamped medicine foil, blister foil, capsule aluminum foil plate, etc.

- 3) Food packaging: container foil, meal box material, egg tart cup, all kinds of food packaging, sealing foil, etc.

- 4) Industrial applications: tape foil, aluminum foil for electronic cables, honeycomb foil, etc.

-

8011 aluminum foil roll for milk powder can easy open end eoe

8011 aluminum foil roll for milk powder can easy open end eoe

-

1060 1070 8011 Aluminum Sheet Coil Strip for Cosmetic Bottle Cap

1060 1070 8011 Aluminum Sheet Coil Strip for Cosmetic Bottle Cap

8011 Aluminum foil production technology for bottle caps

8011 bottle cap material process needs to go through

- cold rolled

- Rolled foil annealing thickness

- annealing

- Rolled foil finished product

- Tension bending and straightening

- Cutting etc.

After the coil is produced, it must go through processes such as leveling machine cutting, painting, drying, multiple stampings, and anti-counterfeiting markings to finally produce qualified aluminum foil for bottle cap materials.

8011 aluminum sealing plate printing process

Base Treatment (Called "primer, " base treatments are done to help paint adhere better. Products treated with chromate phosphate or zirconium are often cut.)

Exterior (interior) paint Depending on the product, you can paint the sides or product sides first.

Appearance printing (number of printing passes depends on the image to be printed on the cap). -Top coat varnish varnish

Cutting (the sheet is cut into three equal strips using the single cutter method. For some products, both edges are trimmed at this point).

8011 Aluminum for Closure Caps Manufacturer

Haomei Aluminum is a professional manufacturer of 8011 aluminum foil for bottle caps. It provides high-quality aluminum anti-theft bottle cap material 8011 aluminum foil. Its hardness is between H14-H24, tensile strength is between 110-320, elongation is generally not less than 4, water Grade A has a low ear-making rate and can meet special requirements such as high-temperature cooking and sterilization. It is widely used in liquor bottle caps, red wine bottle caps, cosmetic bottle caps, milk powder caps, medical bottle caps, beverage bottle caps, yogurt bottle caps, etc.

Related

- 8011 8011A Aluminium Sheet, Strip and Foil for Caps

- 8011 Aluminium Foil Price Per Ton for Lids

- 8011 O, H14, H24 Aluminum Sheets for Bottle Cap

- 8011 Aluminum Foil for Closure Caps

- 8011 Color Lacquered Aluminum Sheet for Wine Bottle Cap

- Food Grade Alloy 8011 Pre-Painted Aluminum Coil for Bottle cap

- 8011 aluminium sheet for PP cap ROPP cap

- 8011 h14 Aluminum Closure Sheet

- Alloy 8011 aluminium sheet for ropp caps

- 8011 aluminium lacquered sheet for PP cap ropp caps

- Mill Finish Aluminum Foil for Cap 8011 h14

- 8011-H14 aluminium sheet for pharmaceutical closures caps

- 8011 Aluminum Foil for Closure Caps

- 8011 alloy Aluminium strips for aluminum closure/cap

- 8011 H14/H16 aluminum closure sheet for screw caps

- One Side Lacquered Clear Lacquer Pilfer Proof Caps Ropp Caps 8011

- 8011 Aluminum Coil Sheet for Ropp Caps

- 8011 Aluminium Sheet Coil for PP Cap, ROPP

- 8011 Aluminium closure sheet for aluminum Bottle Cap, pp cap

- 8011 Aluminum Sheet for Cap

- 8011 printed aluminium closure sheet for bottle cap

- 8011 Aluminum Strip for Caps

- 8011 aluminum sheet for bottle caps

- 8011-H14 Aluminum closure sheet plate manufacturer

- 8011 H16 aluminum alloy bottle cap material

- 8011 Aluminium closure sheet for aluminum Bottle Cap, pp cap

- 8011 Aluminium Sheet for Closure Applications

- 8011 Aluminum ROPP Cap

- 8011 Clear Lacquered Aluminum Foil

- 8011 aluminum foil for closure caps with good price

- Excellent Sealing 8011 Aluminum Cap Closure

- 8011 Aluminium Wine Closure Sheet for Screw Caps

- 8011 Ho Aluminum Coil for Wine Medicine PP Cap

- 8011 Aluminium closure sheet

- 8011 3105 Aluminum Sheet for Cap Closure

- Both Side Lacquered Clear Lacquer 8011 Aluminum Sheet for Closure PP Caps

- 8011 Aluminium Sheet for Pilfer Proof Caps

- Pilfer-Proof Caps|ROPP Cap Aluminum Foil 8011

- 8011 Aluminium Sheets for Pilfer Proof Caps Wine Cap

- 8011 Aluminum Cap Closure Foil

- Aluminium sheet 8011 h14 for pilfer proof caps

- 8011 aluminium sheet for PP cap ROPP cap

- 8011-H16/H18 Aluminum plate foil for deep drawing bottle caps

- 3105 8011 Aluminum Sheet Aluminium closure

- 8011 aluminum foil for perfume bottle cap material

- 8011 aluminum strip for vial seals

- Hot rolling Aluminum Coil 8011 H18 H19 for wine cap

- aluminium closures bottle cap sheet 8011 for pilfer proof cap

- 8011 aluminium plain lacquered strip

- 8011 aluminum sheet for jar cap