8011 3105 Aluminum Sheet Coil for Screw Caps

Aluminum sheet rolls for screw caps play a vital role in the packaging industry, especially in sealing beverages and pharmaceuticals.

Aluminum coils are commonly used to produce screw caps for a variety of containers, including bottles and jars. These screw caps are widely used in industries such as food and beverages, pharmaceuticals and cosmetics.

Key points of aluminum plate coils for screw caps

- 1. Material: Aluminum sheet rolls used for screw caps are usually made of high-quality aluminum alloy, such as 8011, which has good formability, corrosion resistance and strength properties.

- 2. Thickness: The thickness of aluminum sheet rolls used for screw caps can vary according to the specific requirements of the application. But usually in the range of 0.18mm to 0.23mm.

- 3. Coating: Aluminum coils used for screw caps usually undergo a surface treatment process to improve their corrosion resistance, enhance the adhesion of the coating, and provide a decorative finish. This may include coatings such as varnishes or organic coatings.

- 4. Forming: Special equipment such as a stamping machine is usually used to roll aluminum sheets into screw caps. The coil is fed into the machine, where it undergoes a series of forming operations to shape it into the desired cap design.

- 5. Features: Screw caps made from aluminum sheet rolls have multiple advantages, including being lightweight, durable and recyclable. They also provide an effective seal to protect the contents of the container from contamination and oxidation.

- 6. Customization: Aluminum coils can be customized to meet specific requirements in size, shape, color and printing. This enables manufacturers to create screw caps that match their brand and product specifications.

- 7. Quality control: During the manufacturing process, quality control measures are crucial to ensure that aluminum coils meet the required standards for thickness, surface finish, and dimensional accuracy.

Performance of aluminum coils for screw caps

Aluminum sheet coils for screw caps have several properties that make them an ideal material for packaging applications.

- 1. Sealing performance: Aluminum screw caps have excellent sealing performance, helping to prevent leakage and oxidation, thereby maintaining the freshness and integrity of the product.

- 2. Durability: Aluminum is a durable material that can withstand handling and shipping, ensuring that screw caps remain intact during distribution and storage.

- 3. Light weight: Aluminum screw caps are lightweight, which helps reduce shipping costs and energy consumption during transportation compared to heavier materials.

- 4. Corrosion resistance: Aluminum has corrosion resistance and is suitable for use in various environmental conditions without affecting the integrity of the nut.

- 5. Formability: Aluminum coils can be easily formed into various shapes and sizes without sacrificing their mechanical properties. This formability is critical to manufacturing screw caps with precise dimensions and tight sealing capabilities.

- 6. Compatibility with sealing technologies: Aluminum sheet coils are compatible with a variety of sealing technologies, including induction sealing and compression molding. This compatibility ensures reliable sealing of the product and prevents leakage or contamination.

- 7. Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice for packaging materials. The recycled aluminum can be used to produce new screw caps, contributing to sustainable development.

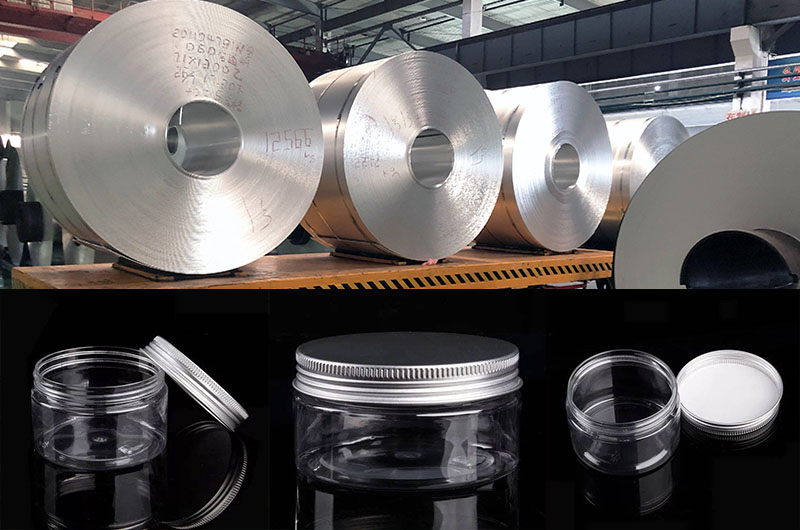

Specification of aluminum sheet for screw caps

| Alloy | 3105/8011 |

| Temper | H14, H16, H44, H46 |

| Thickness | 0.2-0.25mm |

| Width | 500-1000mm |

| Length | 500-1000mm |

| Application | closures for carbonated drinks & mineral waters. |

Alloy 8011: This alloy is commonly used in screw caps due to its excellent formability, corrosion resistance, and suitability for deep drawing. It is commonly used in the food and beverage industry.

Alloy 3105: Alloy 3105 is another popular choice for screw caps, offering good strength and formability. It is commonly used in applications requiring high strength and corrosion resistance.

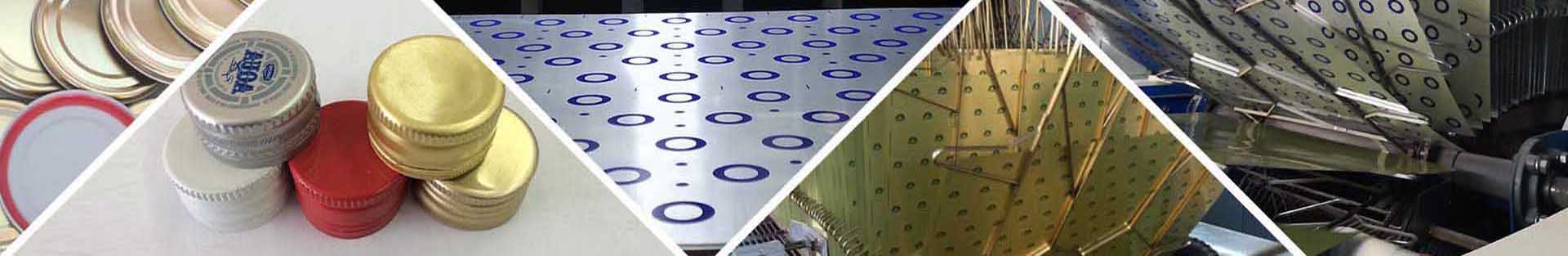

Aluminium Screw Cap Common sizes

- 63mm Aluminium Screw Cap

- 53mm Aluminium Screw Cap

The choice of alloy depends on the specific requirements of the application, such as the type of seal contents, manufacturing process and environmental conditions. For example, if screw caps are used in the food and beverage industry, alloys with good corrosion resistance and suitable for food contact are preferred. Likewise, if a nut needs to withstand harsh environmental conditions, an alloy with high corrosion resistance will be chosen.

Surface type of aluminum sheet for bottle screw caps

- Plain mill finish

- DOS oil lubricated finish

- Chromated finish

- One side golden/white/red/blue/black, etc. other side protective lacquered

- Both sides clear/transparent lacquered

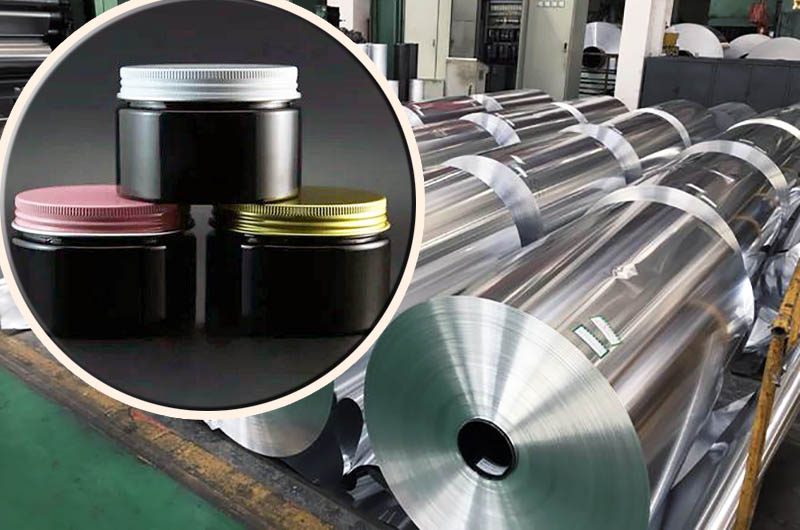

Applications of aluminum coil for screw caps

Aluminum screw cap for beverage packaging

Aluminum screw caps are widely used for sealing bottles of carbonated drinks, mineral water, juice, alcoholic beverages, etc. Aluminum's excellent sealing properties ensure the freshness and integrity of packaged beverages.

Aluminum screw cap for pharmaceutical packaging

Aluminum screw caps are commonly used in pharmaceutical packaging to seal bottles containing liquid medications, syrups, and oral solutions. The tamper-resistant features of the aluminum cover ensure product security and integrity.

Aluminum screw cap for cosmetic packaging

Aluminum screw caps are a popular choice for sealing cosmetic bottles and containers such as lotions, creams and perfumes.

Aluminum screw cap manufacturing process

The manufacturing process of aluminum sheet coils for screw caps involves several stages.

- 1. Aluminum material

- 2. Continuous casting

- 3. Rolling

- 4. Surface treatment

We control material composition, rolling temperature and time, and annealing temperature to produce the best material to meet our customers' performance needs, such as opening capacity and ear yield.

With good flatness and squareness, it can prevent color gaps, unevenness or printing misalignment problems during the printing process.

Haomei Aluminum is committed to the research and development and production of aluminum caps materials such as PP caps, ROPP caps, screw caps, wine caps, vial seal etc. With a complete production system and numerical control equipment, the quality of the end product is controllable and the price is reasonable.