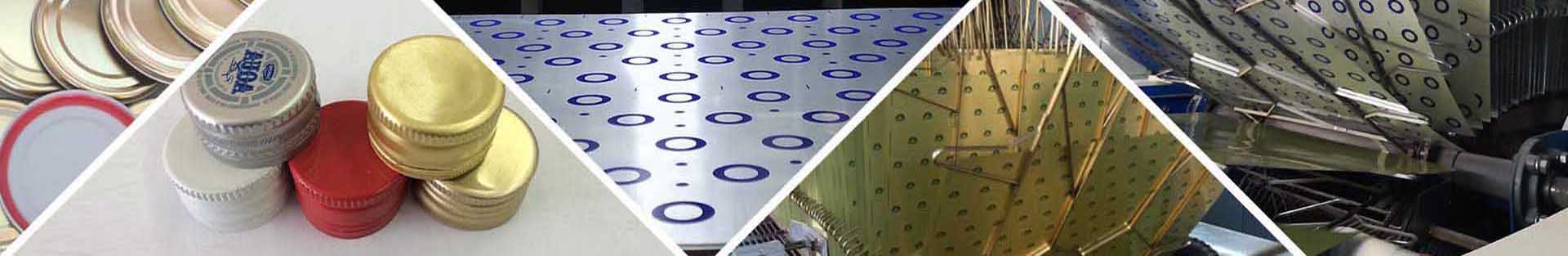

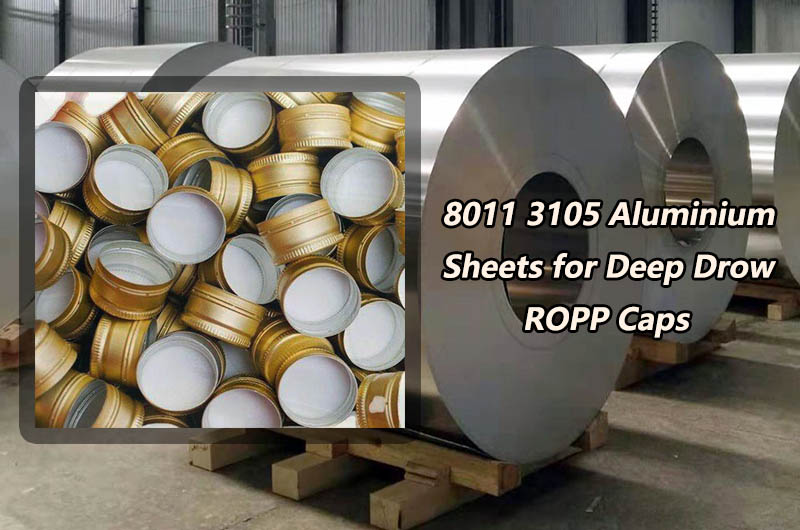

8011 3105 Aluminium Sheets for Deep Draw ROPP Caps

One of the key components of packaging, especially in the beverage and pharmaceutical industries, is the closure system. Roll-off pilfer-proof (ROPP) lids play a critical role in ensuring the integrity, safety and freshness of package contents.

Ropp covers 3105 and 8011 are made of aluminum for optimal stretchability and paint adhesion. The most commonly used aluminum alloy for ROPP bottle caps is 8011 alloy, which has good formability, good ear forming rate and flatness to ensure the deep drawing of long bottle caps. It is commonly used as ROPP caps for wine bottles and other beverage bottles.

ROPP Caps are made of plain aluminum sheets of different thicknesses and equipped with EPE lining, which can be used to seal glass/plastic bottles to prevent theft. This ensures that the product is not tampered with. The hat can also be customized with your logo.

ROPP Caps are equipped with a layer of reinforced polyethylene (EPE) inside, ensuring the bottle is completely leak- and spill-proof. It also provides a level of protection to the contents of the container from environmental factors and limits evaporation.

Roll-on Pilfer Proof caps or ROPP caps are a type of bottle closure made out of aluminum, widely used in pharmaceutical, chemical and food and beverage industries. More than just a closure or cap, it serves as an effective seal for the bottle, ensuring the purity of the packaged medicines by preventing adulteration and illegal tampering. A simple twist breaks the seal, making it quite consumer-friendly.

Learn about Aluminium ROPP caps

ROPP covers are widely used in industries that require a secure sealing mechanism. They are commonly used in the bottling of beverages such as wine, spirits and carbonated drinks, as well as pharmaceutical products such as syrups and pharmaceuticals. ROPP caps are designed to be tamper-proof, ensuring the integrity of the product before it reaches the end consumer.

8011 aluminum plate is a commonly used aluminum plate used for deep-drawn ROPP covers. The aluminum plate has excellent moisture resistance, light-shielding properties and high barrier capabilities. Therefore, 8011 aluminum plates are widely used in manufacturing various packaging closures, such as wine bottle caps, beverage bottle caps, food bottle caps and medicine caps, etc.

Why does ROPP cover use aluminum plate?

Aluminum has become the material of choice for ROPP caps due to its inherent properties that suit packaging applications. Aluminum has excellent barrier properties, protecting contents from light, moisture and other external factors that can affect quality. Additionally, aluminum is lightweight and strong, making it ideal for shipping and handling.

Aluminum Sheet For ROPP Caps advantages

One of the main benefits of ROPP aluminum covers is their tamper-resistant features. Once the cap is sealed to the bottle, any attempt to open the cap will result in clear signs of tampering.

- 1. Tamper Resistant: ROPP covers provide excellent tamper resistance. Once the cap is on and sealed to the bottle, it takes a lot of force to remove it. Any attempt to open the bottle will result in visible damage to the cap, indicating that the product may have been tampered with.

- 2. Secure seal: ROPP bottle caps create a tight seal, helping to maintain the freshness and integrity of the product inside the bottle. This is particularly important for products such as beverages, pharmaceuticals and chemical solutions where quality needs to be maintained over time.

- 3. Durability: ROPP bottle caps are usually made of aluminum or other strong materials and are very durable. This durability ensures the cap remains intact during handling, shipping and storage, minimizing the risk of leakage or contamination.

- 4. Beautiful: ROPP bottle caps can be customized in a variety of designs, colors and finishes to enhance the overall appearance of product packaging. This customization enables brands to create unique and attractive packaging solutions that appeal to consumers.

- 5. Recyclability: Aluminum ROPP covers are fully recyclable, contributing to sustainability and reducing environmental impact. By using recyclable materials, brands can demonstrate their commitment to environmental responsibility and attract environmentally conscious consumers.

- 6. Compatibility: ROPP bottle caps are compatible with a variety of bottle types and sizes, providing versatility for packaging a variety of products. This compatibility makes ROPP caps a popular choice in industries such as food and beverage, pharmaceuticals, cosmetics and household chemicals.

- 7. Cost-Effectiveness: While the initial cost of ROPP caps may be higher compared to some other types of caps, their durability and tamper-resistant features help reduce the risk of product loss due to tampering or leakage. Additionally, the ability to customize ROPP caps enables brands to create premium packaging solutions that justify the investment.

Aluminum Sheets for ROPP Caps Drawing process

The manufacturing process for ROPP bottle caps involves deep drawing, a metal forming technique used to create complex shapes from sheet metal.

We use state-of-the-art technology to manufacture ROPP closures, maintaining consistency in every batch of these widely accepted closures. Our closures keep products safe from tampering. Moreover, consumers receive products that retain their original ingredients and purity.

Aluminum Sheet for ROPP Caps Mechanical Properties

| Alloy (AA) | 3105 | 8011 | |||

| Temper | H14 | O | H14 | H24 | |

| UTS (mpa) | Min | 150 | 8.5 | 125 | 125 |

| Max | 200 | 12 | 170 | 160 | |

| % E (min) | (at 50 mm gauge length) | 1 | 15 | 1 | 1 |

Aluminum Sheet for ROPP Caps Chemical Composition

The composition of the aluminum sheets used in deep-drawn ROPP covers is engineered to meet the stringent application requirements. Alloy selection plays a critical role in determining a material's formability, strength and corrosion resistance.

The aluminum used for ropp covers 3105 and 8011 has the highest stretchability and paint adhesion, guaranteeing the highest quality printing of drawings and designs. The most common aluminum alloy for ROPP bottle caps is 8011 alloy, which has good formability, good earring rate and flatness, thus ensuring long cap deep drawing. It is commonly used as ROPP caps for wine bottles and other beverage bottles.

| Alloy (%) | AA 3105 | AA 8011 |

| Fe | 0.70 | 0.6 _ 1.0 |

| Si | 0.60 | 0.5 _ 0.9 |

| Mg | 0.20 _ 0.80 | 0.05 |

| Mn | 0.3 _ 0.8 | 0.20 |

| Cu | 0.30 | 0.10 |

| Zn | 0.25 | 0.10 |

| Ti | 0.10 | 0.08 |

| Cr | 0.10 | 0.05 |

| Each (others) | 0.05 | 0.05 |

| Total (others) | 0.15 | 0.15 |

| Al | Remaining | Remaining |

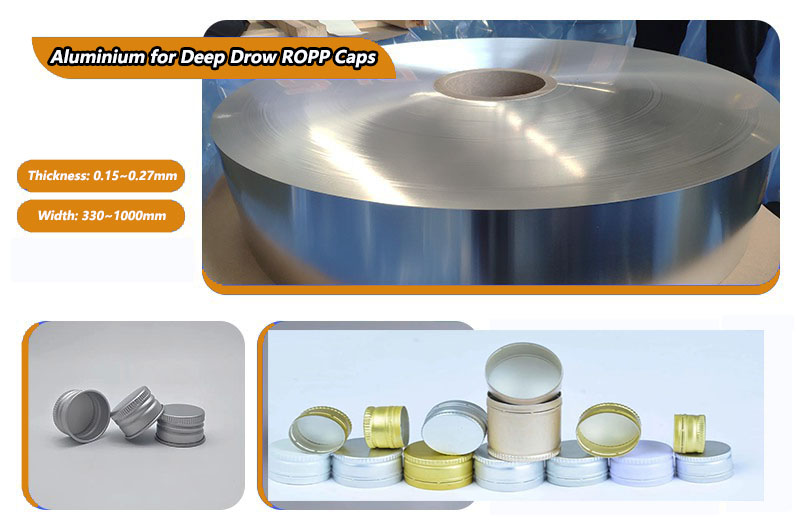

Aluminum Sheets thickness selection for Deep Draw ROPP Caps

When choosing to use aluminum plates for deep-drawn ROPP caps, you need to choose the appropriate specifications and thickness according to actual needs. Generally speaking, the thickness of the aluminum plate used for bottle caps is between 0.15~0.27mm, and the width is between 330~1000mm.

Pay attention to the quality and performance of the aluminum plate to ensure that it can meet the requirements of long-term use. The thickness, quality and performance of the aluminum sheet used for ROPP bottle caps are very important factors when manufacturing bottle caps.

Aluminium ROPP Caps Common sizes

- 25mm Aluminum Sheet for ROPP Caps

- 22mm Aluminum Sheet for ROPP Caps

- 28mm Aluminum Sheet for ROPP Caps

- 31.5mm Aluminum Sheet for ROPP Caps

- 38mm Aluminum Sheet for ROPP Caps

- 46mm Aluminum Sheet for ROPP Caps

- 53mm Aluminum Sheet for ROPP Caps

If the bottle cap is tall and deeply recessed, a thicker 8011 aluminum plate is required to ensure sufficient strength and stability. At the same time, you also need to pay attention to the surface quality and processing accuracy of the aluminum plate to ensure that the ROPP cover has a beautiful appearance, good sealing and usability.

When choosing 8011 aluminum plate for deep-drawn bottle caps, you need to consider its quality, performance and price, make a selection based on actual needs, and ensure that its quality and performance meet the requirements. At the same time, you also need to pay attention to the manufacturing process and use environment of the aluminum plate to ensure that it can meet the requirements of long-term use.

Aluminium Sheets for Deep Draw ROPP Caps Surface Treatment

Surface treatment technology is used to further enhance the performance of aluminum sheets for ROPP covers. For example, anodizing provides a protective layer of oxidation on aluminum surfaces, improving corrosion resistance and surface finish. Additionally, a lubrication system is used during the deep drawing process to reduce friction and promote smooth material flow, thus minimizing defects such as wrinkling and tearing.

- Solid gold, silver and white hat

- Custom Logo Printed ROPP Cap

- Top embossed lid

So whatever your requirements, we offer you high quality, unique and customizable ROPP bottle caps in all available standard sizes.

The Specification of Aluminum Sheet for ROPP Caps

| Alloy | 8011/3105 Aluminum Alloy |

| Temper | H14, H16, H18, H24, H26, H44, H46 |

| Thickness | 0.15-0.45mm |

| Type | Sheet/Coils/Foils/Strips |

| Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oitreated. |

| Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

Advantages of ROPP aluminum plate for bottle caps

1. Enhanced formability

Advanced alloys and surface treatments improve the formability of aluminum sheets, allowing the production of complex cap designs with deep drawing and intricate features.

2. Increase productivity

Process optimization and automation increase productivity, shorten cycle times and increase throughput, helping to save costs and improve competitive advantage.

3. High-end

Enhanced material properties and surface treatments ensure consistent quality and dimensional accuracy of ROPP caps, reducing the risk of defects and product recalls.

4. Environmental sustainability

Aluminum is inherently recyclable, and using advanced aluminum plates on ROPP caps promotes sustainability by reducing resource consumption and waste generation throughout the product life cycle.

5. Safety

The tamper-evident features and strong seal provided by ROPP lids enhance consumer safety and confidence in the integrity of packaged products, particularly in the pharmaceutical and food industries.

Common 8011 Aluminum Sheets Coil for Bottle Cap Materials

Typical applications of Haomei Aluminum cap materials