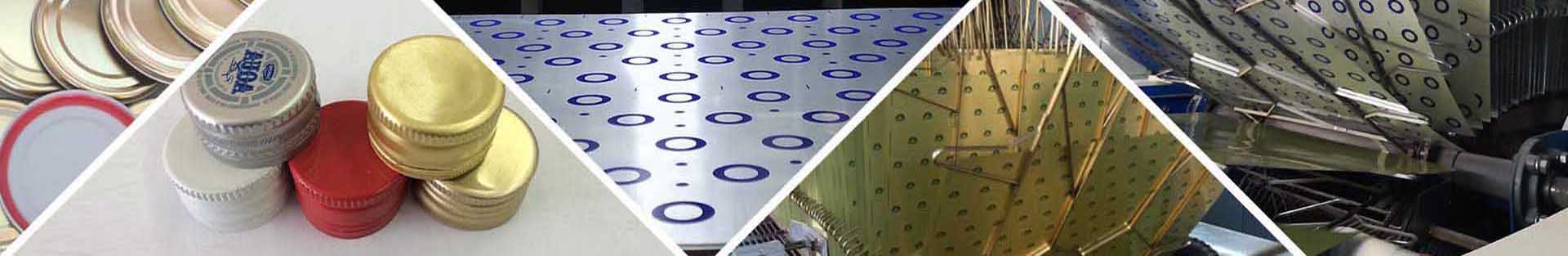

Lacquered Aluminum for Closure Caps

Lacquered aluminum closures are a common packaging solution used in a variety of industries, especially in the food and beverage industry. These lids are commonly used to seal bottles and containers, ensuring product is fresh, tamper-proof and easy to dispense.

Lacquered Aluminum for Closure Caps material

Lacquered aluminum closures are primarily made of aluminum, a lightweight and durable metal known for its corrosion resistance. The aluminum sheet used for these lids is typically coated with a food-grade varnish that provides additional corrosion protection and enhances the appearance of the lid.

The aluminum alloy most commonly used for painted closures is 8011. This alloy is favored for its combination of strength, formability and corrosion resistance, making it ideal for applications in the packaging industry. 8011 aluminum alloy typically contains elements such as silicon, iron, copper, manganese and magnesium, which help improve its mechanical properties and formability.

| Property | Description |

| Aluminum Alloy | 8011 |

| Composition | Contains silicon, iron, copper, manganese, and magnesium |

| Temper Condition | H14 or H16 (Cold worked and partially annealed for a balance of strength and ductility) |

| Thickness | Typically ranges from 0.18 mm to 0.25 mm |

| Surface Treatment | Cleaning and chemical treatment to promote adhesion and ensure uniform coating application |

| Coating | Food-grade varnish/lacquer |

| Purpose of Coating | Provides additional corrosion protection and enhances appearance |

| Applications | Used in food and beverage, pharmaceuticals, personal care products, and household products industries for sealing bottles and containers |

| Key Properties | Lightweight, durable, corrosion-resistant, strong, formable |

| Typical Features | May include a threaded skirt, tamper-evident band, and liner for a secure seal |

| Customization Options | Wide range of color options, metallic finishes, vibrant colors, matte or glossy textures, printed or embossed brand logos and product information for enhanced brand visibility |

Sealing caps are available in various designs and sizes to fit different types of bottles and containers. The design may include features such as a threaded skirt to screw onto the bottle neck, a tamper-evident band to indicate whether the product has been opened or tampered with, and a liner made of materials such as foam or plastic to provide a secure seal.

Lacquered Aluminum for ROPP Caps

Lacquered Aluminum for ROPP Caps are mainly used in the beverage, pharmaceutical and cosmetic industries to ensure product safety and tamper resistance.

Lacquered Aluminum for ROPP Caps Advantages

- Corrosion resistance: The varnish coating protects aluminum from oxidation and corrosion, which is especially important for beverages and pharmaceuticals.

- Aesthetic appeal: Lacquered aluminum has a glossy and attractive surface that can be customized in a variety of colors and designs, enhancing product branding.

- Sealing Performance: Ensures an airtight and secure seal, maintains product integrity and prevents contamination.

- Durability: The paint layer increases the structural strength of the aluminum, making it more resistant to dents and deformation.

Lacquered Aluminum for PP Caps Similar to ROPP caps, PP caps are used to seal bottles, provide tamper resistance and ensure the integrity of the contents. Usually a screw or snap mechanism is used and is suitable for a variety of bottle types.

Lacquered Aluminum for PP Caps Advantages

- Enhanced Protection: The varnish coating protects the aluminum from environmental factors, ensuring a longer shelf life and maintaining the appearance of the cap.

- Customization: Allows for high-quality printing and finishing options so detailed brand and product information can be displayed.

- Safety: Provides a non-reactive barrier, which is critical for products sensitive to metal contamination, such as food and pharmaceuticals.

- Recyclability: Aluminum is highly recyclable and using Lacquered aluminum lids contributes to a sustainable packaging solution.

Lacquer coating: The aluminum plates used for closures are lacquered and serve a variety of purposes.

- First, the varnish provides a smooth and even surface finish that enhances the aesthetics of the closure.

- Secondly, it acts as a protective barrier, preventing aluminum from coming into direct contact with the contents of the bottle, thereby ensuring product safety and maintaining the integrity of the packaged goods.

Lacquered aluminum closures can be customized to meet the branding and packaging requirements of different products. Clearcoat coatings are available in a variety of color options, including metallic finishes, vibrant colors, and matte or glossy textures. Additionally, closures can be printed or embossed with brand logos, product information, or other designs to increase brand awareness and consumer appeal.

Lacquered Aluminum for Closure Caps applications

Lacquered aluminum closures are used in a variety of industries, including the pharmaceutical, food and beverage, cosmetics and household products sectors. They are commonly found on bottled water, soft drinks, alcoholic beverages, condiments, sauces, pharmaceuticals and personal care products.

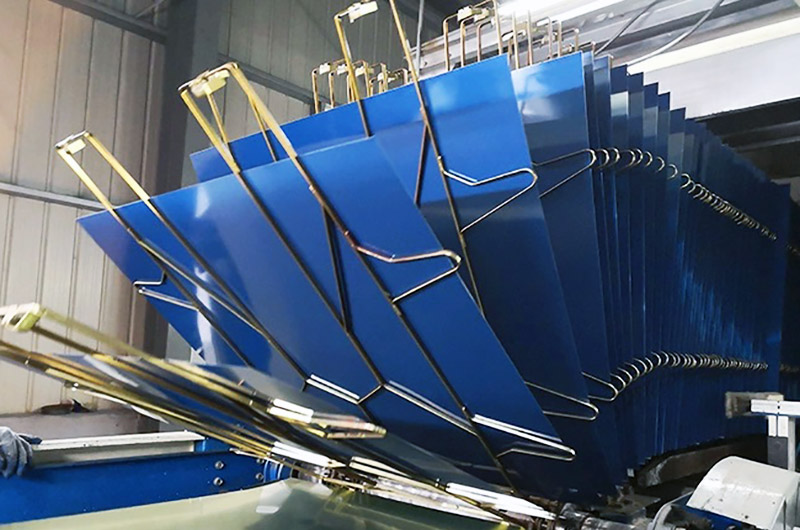

Lacquered Aluminum for Closure Caps production process

- 1. Substrate preparation: High-quality aluminum panels are chosen for their ductility and strength.

- 2. Painting: The aluminum plate is coated with a layer of paint. This can be done by various methods, such as roller coating or spraying.

- 3.The paint is then cured to form a hard, protective surface.

- 4. Form the bottle cap: The Lacquered aluminum plate is cut into blanks, and then the bottle cap is made through a series of stamping and forming processes.

- 5. Printing and decoration: Bottle caps can also be further decorated with logos, text and other designs using techniques such as offset printing, embossing or debossing.

Precautions for use

- 1. Compatibility with contents: Make sure the varnish used is compatible with the contents of the bottle to avoid any chemical reactions.

- 2. Quality Control: Regular inspections and tests should be conducted to ensure the integrity and performance of Lacquered aluminum covers.

Lacquered aluminum is an excellent choice for ROPP and PP covers because of its protective qualities, aesthetic potential and durability. Its use in various industries helps ensure product safety, enhance brand image and support sustainable packaging initiatives.

Lacquered aluminum closures provide a reliable and versatile packaging solution that combines functionality, aesthetics and safety to meet the diverse needs of manufacturers and consumers.